100mm 150mm 200mm Cellular Driveway Geocell

The use of geocells can enhance the stability of the roadbed

Geocells can disperse loads

Provide a water excretion channel

Improve the convenience of construction

Reduce engineering costs

The construction is rapid and the products are environmentally friendly

100mm 150mm 200mm Cellular Driveway Geocell

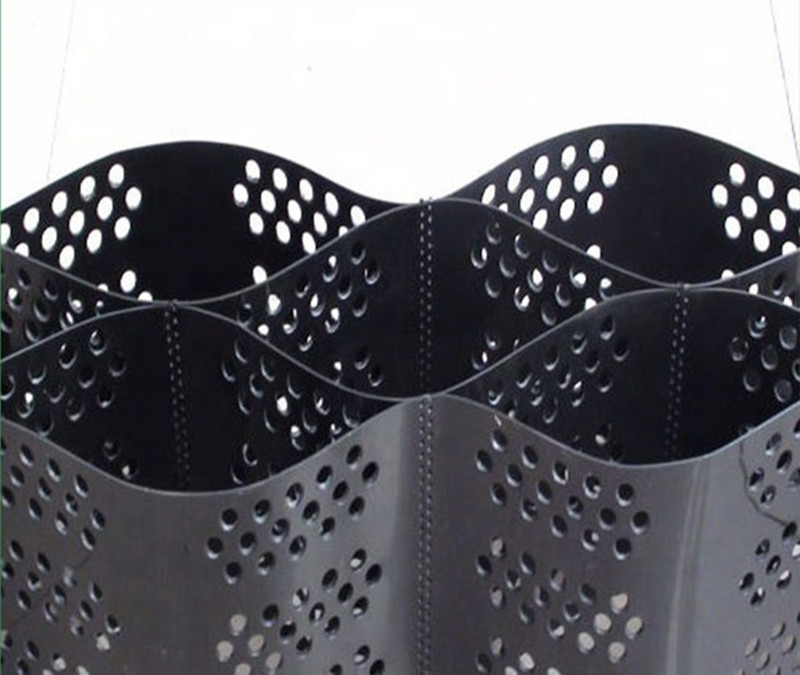

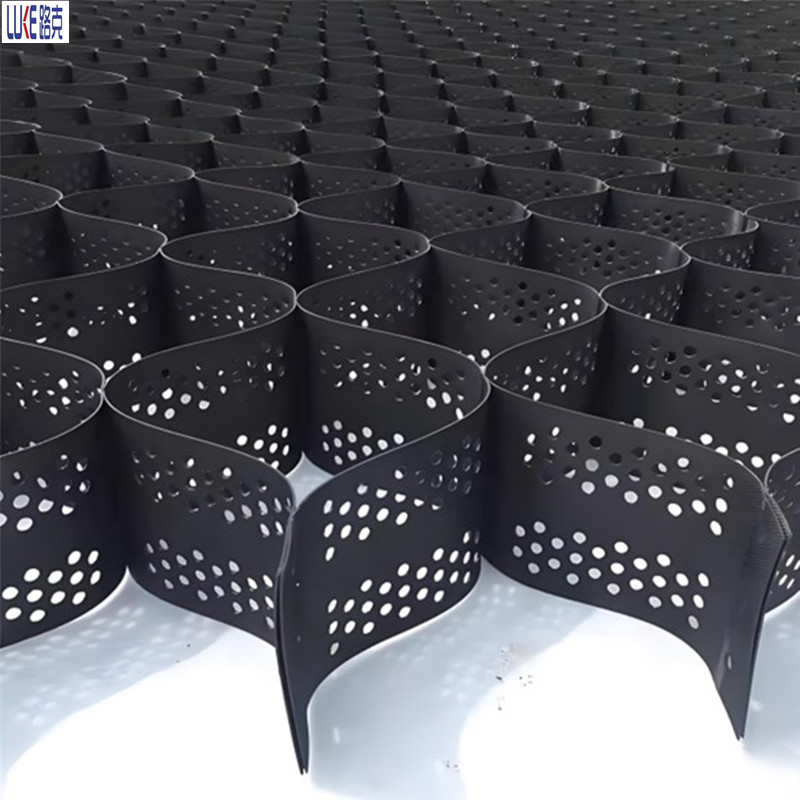

Geocells can be classified in various ways. According to height, they can be divided into 50mm HDPE geocell,10mm HDPE geocell,15mm HDPE geocell and 20mm HDPE geocell. Its material is made of high-density polyethylene, featuring high strength, corrosion resistance and other properties. Different heights have different uses. The 50mm HDPE geocell has a relatively low height, requires less backfill soil during construction, has a relatively low cost, and has a good greening effect. 10mm-20mm HDPE geocell. With the increase of height, the lateral restraint ability and load-bearing capacity of the cell increase, and more soil and stone materials can be filled to form a more solid structural body. HDPE geocells, as a commonly used geosynthetic material, play a significant role in the field of civil engineering.

The HDPE Geocells feature:

◆Low cost Hdpe geocell easy maintenance.

◆The geocell gravel grid is flexible, foldable and easy to transport ,which can be drawn into a network during construction.

◆The hdpe geocells have high side limit and anti-slip, anti-deformation, effectively enhance the bearing capacity of the roadbed and disperse the load.

◆It can change the geocell height, welding distance and other geometric dimensions to meet different engineering needs.

◆Convenient connection and fast construction speed.

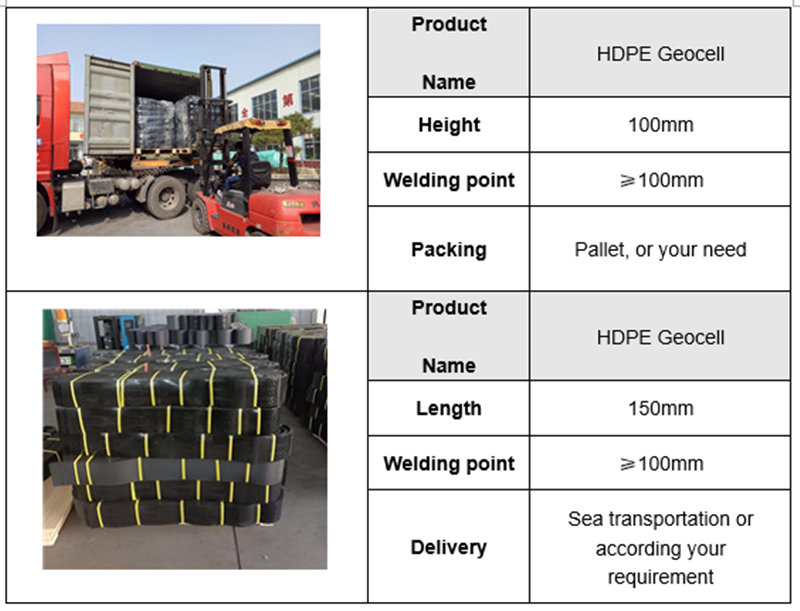

Technical parameters of hdpe geocell:

Product type | Height (mm) | Welding Distance(mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Commenction of Cells(N/cm) | Tensile Strength of Yield of Each Sheet(Mpa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Remaiks: This is a basic technical specification. All the above technical parameters can be reached according to customer’s requirement and other special standard can be carried out by agreement or contract. | ||||||

HDPE geocells Packaging:

The HDPE geocell is packed with pallet.In the packaging of the geocells,it is need to choose packaging materials that resist external pressure and wear resistance.

About our company:

Shandong Luke Composite Co.,Ltd is professional company on production and sales geosynthetics for years.We mainly produce geomembrane,geotextile,drain board,geogrid,geocell,3D geomat,drain mat,drainage net,grass paver etc.Our geosynthetic materials have been exported to more than 30 nations and regions, such as Southeast Asia, Australia, North America, Europe, Middle East and Africa.We can provid the geocell solutions for you.

Our company aim is :quality first,reputation first!

Professional equipment,high quality HDPE geocell,first-class service is your best choice,welcome to our company!

The application of strength HDPE geocell:

◆River revetment: the geocell can effectively prevent the river from scouring the bank and protect the ecological environment of the river.

◆Mountain protection.

◆Dam reinforcement: geocell can effectively strengthen the stability and safety of the dam.

◆Highway tunnel support: Geocell can effectively support the structure of highway tunnel and improve its stability and development.

◆Gravel foundation.

◆Retaining wall.

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to HDPE geocell in a timely manner. Thank you for your love of our products.

HDPE geocell application case:

The application of HDPE geocells in actual engineering, such as "In a highway construction project, HDPE geocells were used for roadbed reinforcement, effectively reducing roadbed settlement. After testing, the settlement amount was reduced by 30% compared to before use, significantly enhancing the stability and service life of the road."

Related Products

Related News

Submitted successfully

We will contact you as soon as possible