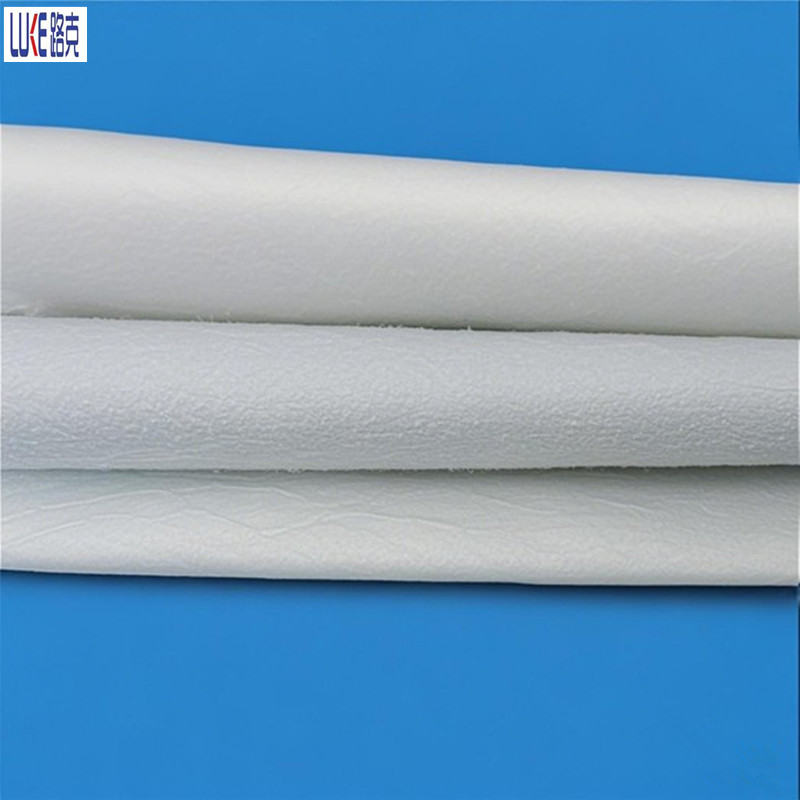

Filament Polyester Geotextile Long Fiber Geofabric

100% Polyester filaments geotextile has good high tensile strength.

Filament polyester geotextile fabric have good resistance to aging, tear and puncture.

Polypropylene or polyester geotextile can resistance to acid and alkali.

Geotextiles has good impermeability and resistance to deformation.

Polyester filament geotextiles are highly durable and resistant to UV degradation, chemicals, and biological degradation, ensuring long-term performance even in harsh environmental conditions.

Filament Polyester Geotextile Long Fiber Geofabric

Polyester filament geotextiles and short-fiber geotextiles are both commonly used geosynthetic materials, but they have obvious differences in raw materials, production processes, performance characteristics and application scenarios. The following are the specific differences:

The raw material of filament polyester geotextile is polyester chips, which are made of high-purity and high-molecular-weight polyester polymers. The raw materials of short-fiber geotextiles are also polyester chips, but other fibers such as polypropylene may also be mixed in.

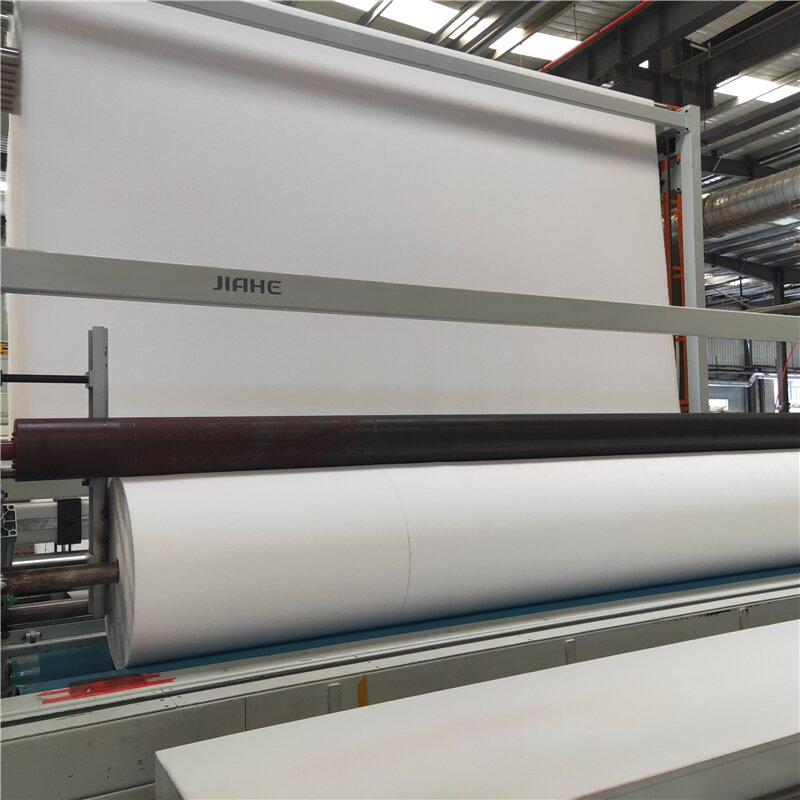

Polyester filament geotextiles are made into continuous filaments through melt spinning. The filaments are carded into a web and then needled and reinforced (or thermally bonded) to form fabrics. The fibers are closely combined with each other, and there are no short fiber breaks. Short-fiber geotextiles are first made by melt spinning polyester chips into short fibers. After the short fibers are loosened and carded into a web, they are consolidated into fabric through needling or chemical bonding processes. The fiber ends are exposed and the surface is relatively rough.

Long-fiber geofabric has high strength, stable water permeability, good corrosion resistance and wear resistance, and strong durability. Short-fiber geotextiles have low strength, fluctuating water permeability and poor wear resistance, but they are low in cost and easy to construct.

Polyester Geotextile fabric advantages:

◆High Tensile Strength: Filament polyester geotextiles are known for their high tensile strength, which makes them suitable for applications requiring reinforcement and stabilization, such as road construction and embankment reinforcement.

◆Durability: These geotextiles are highly durable and resistant to UV degradation, chemicals, and biological degradation, ensuring long-term performance even in harsh environmental conditions.

◆Excellent Filtration Properties: They provide effective filtration by allowing water to pass through while retaining soil particles, which helps in preventing soil erosion and maintaining the integrity of the structure.

◆Good Drainage: The structure of filament polyester geotextiles facilitates efficient drainage, reducing the risk of water accumulation and associated problems like soil saturation and structural instability.

◆Resistance to Creep: Polyester has a low creep potential, meaning it maintains its shape and strength under constant stress over time, which is crucial for long-term stability in reinforcement applications.

◆Flexibility: These geotextiles are flexible and can conform to the shape of the underlying surface, providing uniform support and stress distribution.

◆Ease of Installation: Filament polyester geotextiles are relatively easy to handle and install, which can reduce labor costs and installation time.

◆Cost-Effective: Given their durability and long service life, filament polyester geotextiles can be a cost-effective solution for many engineering projects, reducing the need for frequent replacements or repairs.

◆Environmental Benefits: By preventing soil erosion and promoting vegetation growth, these geotextiles can contribute to environmental conservation efforts.

The parameters of filament polyester geotextiles:

Geotextile Type | Non-Woven Geotextile |

Type | Filamen Geofabric |

Width | 2-6m |

Application | Building Construction |

Material | PP(polypropylene)PET(polyester) |

Color | White, Black, Green |

Function | Filter, Reinforcement, Protection |

Weight | 100-800g/㎡ |

Certificate | ISO9001 |

Package | Plastic Woven Bags |

Lead time and packaging of Filament polyester geotextiles:

Quantity(square meters) | 1-6000 | 6001-30000 | >30000 |

Lead time(days) | 2 | 5 | To be negotiated |

Woven bag in roll or customer’s requirements.

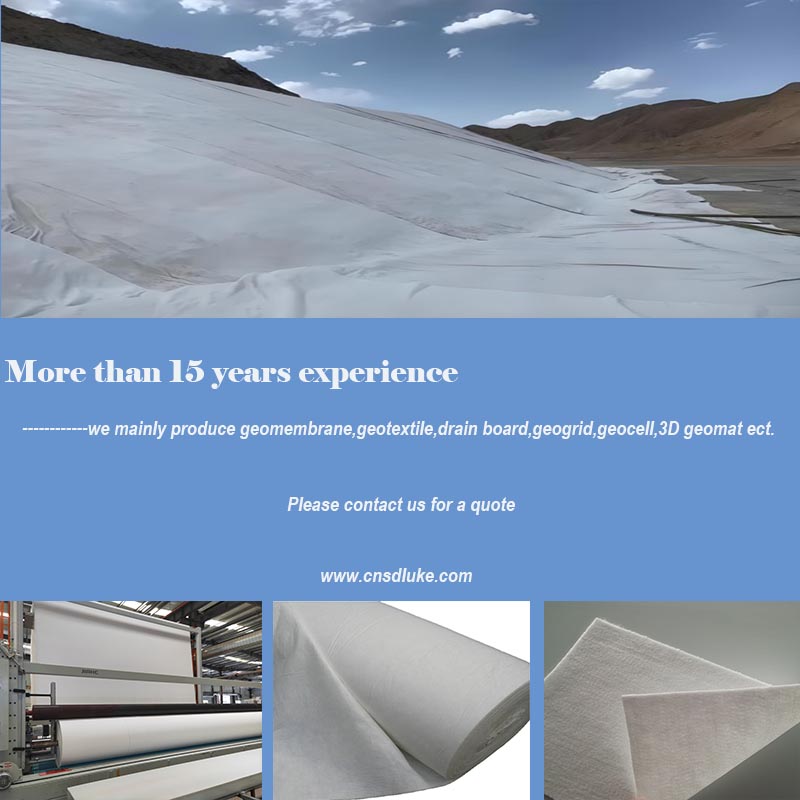

Application fields of filament polyester geotextile Non-Woven geotextile

◆Infrastructure: Reinforcement of roads, railways, and airport runways to distribute loads and prevent soil mixing.

◆Landfill stabilization and erosion control in coastal dunes.

◆Geotextile used for water conservancy systems (riverbank protection, culvert lining).

◆Construction: Separation layers in foundations, slope protection, and waterproofing solutions when combined with asphalt or rubber.

About us:

Shandong Luke Composite Co., Ltd is professional company on production and sales geosynthetics for years. We mainly produce geomembrane,geotextile,drain board,geogrid,geocell,3D geomat,drain mat,drainage net,grass paver etc. Our geosynthetic materials have been exported to more than 30 nations and regions, such as Southeast Asia, Australia, North America, Europe, Middle East and Africa.

Professional equipment, high quality HDPE geocell, first-class service is your best choice ,welcome to our company! If you want to know more about geotextile fabric, you can continue to ask me questions.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible