HDPE Geocells

Geocell has high strength and bearing capacity, which can effectively improve the quality and service life of roadbed and pavement.

The geocell can be flexibly folded during transportation and installation on the construction site.

HDPE geocell can be recycled, environmentally friendly, in line with the requirements of sustainable development.

Geoweb geocell can be installed quickly, shorten the construction period, and improve the construction efficiency.

HDPE Geocells

HDPE (High density polyethylene) geocell, also known as geocell or geoweb geocell, is a three-dimensional honeycomb structural material. Because it is filled into sol, gravel, concrete or other granular materials, to form a structure with strong lateral constraint and high stiffness rate, it is widely used in civil stability, slope protection, retaining wall and other projects. Its main features include:

High strength and durability

◆High tensile strength: HDPE material has excellent tensile strength and can withstand large loads.

◆Corrosion resistance: HDPE has high corrosion resistance to chemicals, acids, alkalis, etc., and is suitable for a variety of complex environments.

◆Anti-aging: HDPE Geocell has good anti-ultraviolet properties and can be used outdoors for a long time without aging.

Three-dimensional honeycomb structure

◆Three-dimensional support: the honeycomb structure can effectively disperse the load and enhance the stability of the soil.

◆Flexibility: It can adjust the height, weld spacing and spread area according to the engineering needs to adapt to different terrain and construction requirements.

Lightweight and easy to install

◆The HDPE Geocell is lightweight and easy to transport and construct.

◆Modular design, easy and quick installation, can greatly shorten the construction period.

Water permeability

Drainage performance: The honeycomb structure of geoweb geocell allows water to flow freely, reducing water pressure damage to the structure, while helping the soil to drain.

Reduce engineering costs: The use of geocell erosion control system reduces the use of traditional materials such as concrete and stone, reducing construction and maintenance costs.

Long life: strong durability, reduce later maintenance costs.

In short, HDPE Geocell is an efficient, economical and environmentally friendly engineering material suitable for a variety of civil engineering scenarios.

Parameter

| Product Type | Height (mm) | Welding Distance (mm) | Thickness (mm) | Tensile Strength of Welding Points (N/cm) | Tensile Strength of Commection of Cells (N/cm) | Tensile Strength of Yield of Each Sheet (Mpa) |

| Smooth and Not Perforated | 50≤H≤250 | 330≤A≤ 1000 | 1.0-1.4 | 2100 | 2120 | 220 |

| Smooth and Perforated | 550≤H≤250 | 330≤A≤ 1000 | 1.0-1.4 | 2100 | 2120 | 220 |

| Textured and Not Perforated | 50≤H≤250 | 330≤A≤ 1000 | 1.0-1.4 | 2100 | 2120 | 220 |

| Textured and Perforated | 50≤H≤250 | 330≤A≤ 1000 | 1.0-1.4 | 2100 | 2120 | 220 |

| Remarks: This is a basic technical specification. All the above technical parameters can be reached according to customer's requirement and other special standard can be carried out by agreement or contract. | ||||||

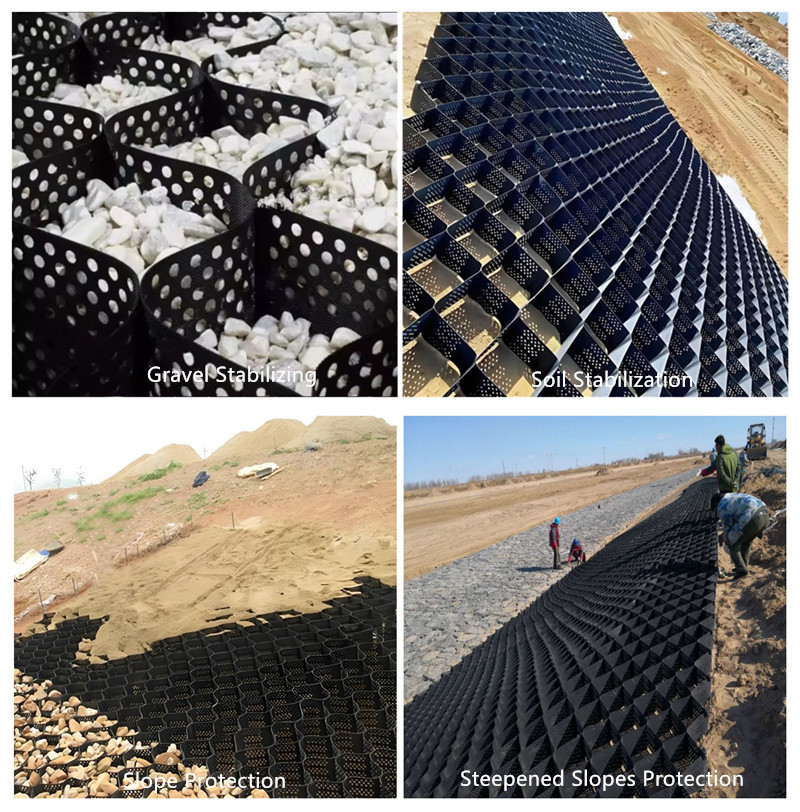

Application

◆Load support: Solve unacceptable road,parking, and yard surface problems.

◆Slope protection: Create a stable environment for long-term sustainability of embankment material.

◆Channel protection:Ensure stability and protection of channels exposed to all types of erosive conditions.

◆Vegetated retaining walls: Includes steepened slopes, retaining walls, gravity walls and so on.

◆Landscaping and gravel stabilizing.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible