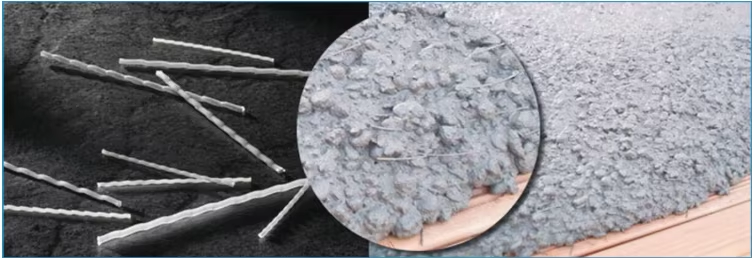

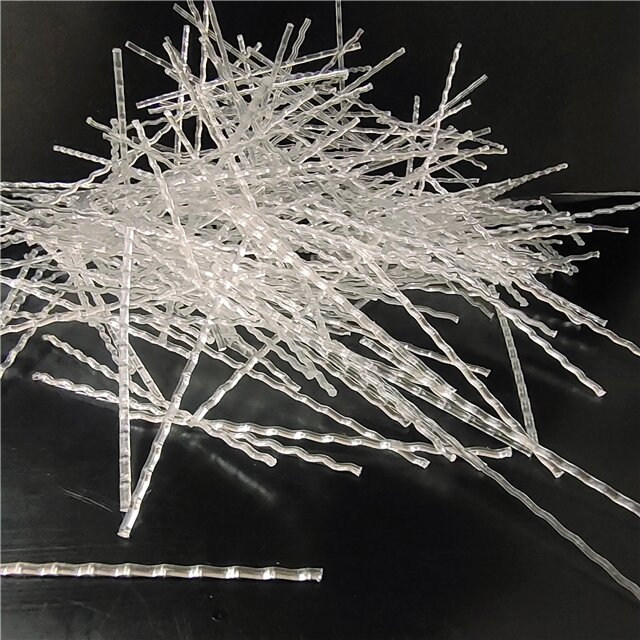

Emobossed High-strength Polypropylene Concrete Fiber

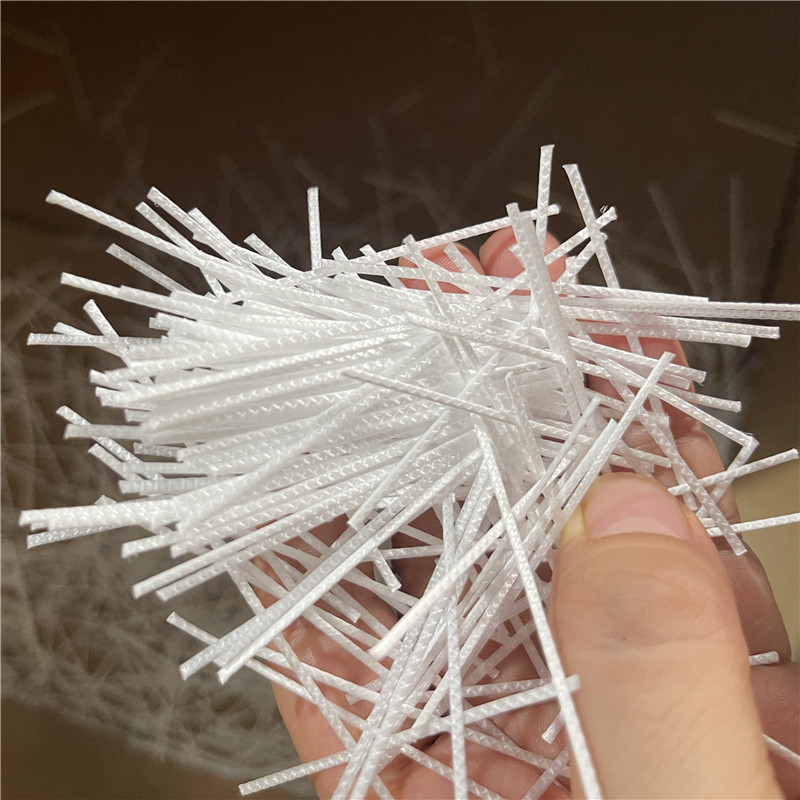

The embossed polypropylene fibers can enhance the bonding performance

at the interface and increase the adhesion to concrete

Effectively suppressing the early shrinkage cracks in concrete

High strength polyproylene macro fibers used for concrete reinforcement

The uneven surface increases the contact area between the polypropylene fibers and the cement slurry

Enhances the interface friction force, and further strengthens the bonding stability.

It has strong acid and alkali resistant.

Tensile strength>600MPa

Emobossed High-strength Polypropylene Concrete Fiber

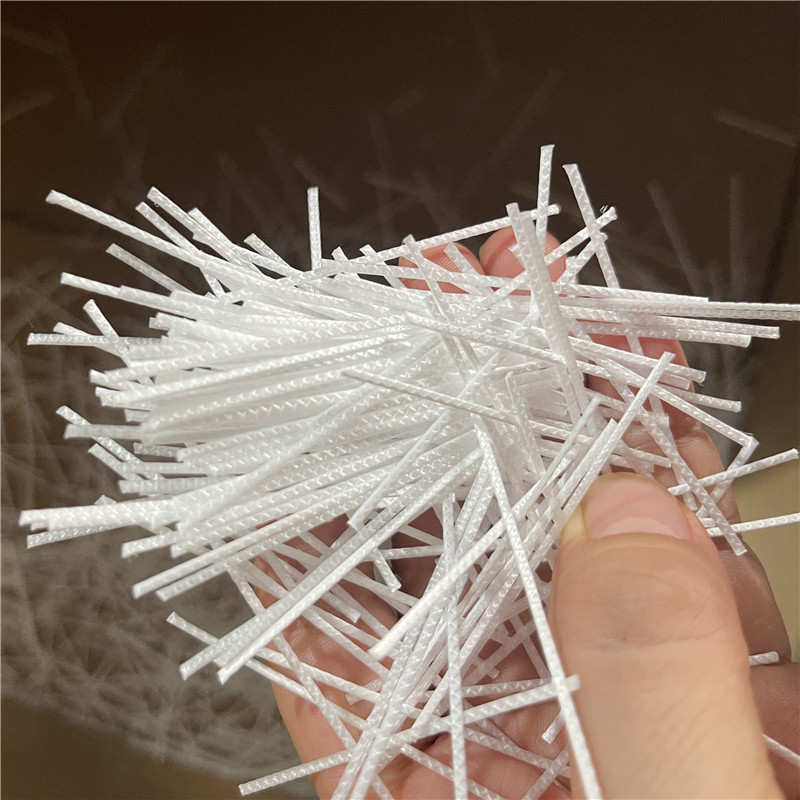

Emobossed polypropylene macro fiber is kind of concrete reinforcing fiber.The surface of ordinary concrete polypropylene fiber is smooth, and their adhesion to the concrete substrate is weak. This makes the pp macro fibers prone to detachment from the concrete, thereby reducing the enhancement effect. The embossed process improves the interface effect by forming uneven patterns on the fiber surface. The smooth fibers have uneven interface adhesion, which can easily form stress concentration points locally, causing the concrete to crack. The embossed structure polypropylene macro concrete fiber enables more uniform stress transmission, avoiding excessive stress in certain areas, and indirectly enhancing the crack resistance of the concrete.

Embossed Polypropylene macro concrete fiber properties:

Raw Materia | 100%Polypropylene | Length(mm) | 20~70 |

Trademark | LUKE | Tensile Strength | >600(MPa) |

Origin | China | Elastic Modulus | ≥4000(MPa) |

Shape | Curved,Embossed, Waved | Equivalent Dia | 0.9±0.2 |

Density(g/cm³) | 0.91 | Crack Elongation | ≥15% |

Color | White,Black,Grey | Melting Point | 160-170℃ |

Resistance Acid alkali | Strong | ||

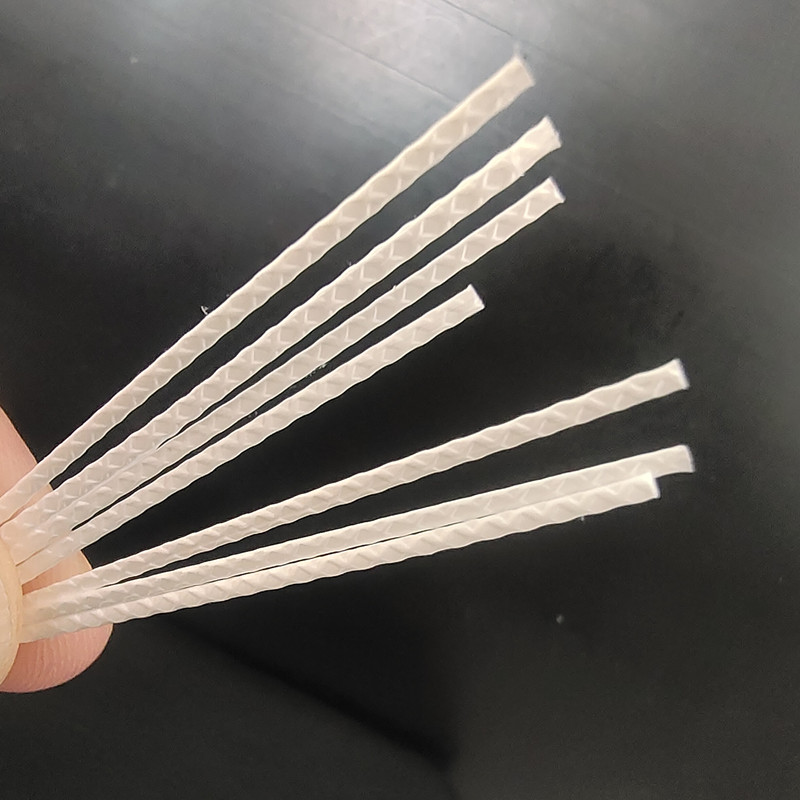

High strength polypropylene(PP) macro fiber feature:

◆Light weight, easy to disperse

◆Enhance strength, toughness and strength.

◆Improve the durability of concrete.

◆It can reduce the leakage of concrete.

◆Polypropylene macro fiber synthetic fiber protect steel from corrosion.

◆Polypropylene fibers in concrete can improve the durability of concrete structures.

Five advantages of concrete reinforcing fiber:

Strong crack resistance: reduce concrete plastic shrinkage cracks.

Corrosion resistance: more suitable for wet, saline-alkali environment than steel fiber.

Convenient construction: no need to worry about puncture wounds or equipment wear like steel fibers.

Economy: The cost is lower than steel fiber, especially suitable for large areas of the floor.

Emobossed concrete polypropylene macro fibers Waved concrete polypropylene macro fibers

High-strength polypropylene fibers packaging and delivery:

You can choice the packaging of carton,woven bag,paper bag or water soluble,pallet.

Plastic packing:1kg pp fibers/plastic bag,20kgs/PP woven bag

Paper packing:600-900g/paper bag,5kgs/carton.

Special packaging can be supplied on your request.

Please contact with us for latest price, thank you.

Customer feedback about polypropylene fiber concrete fiber:

A good product, a customer recognition, this is our greatest success, thank you for our recognition, we will continue to work hard to improve the quality of service.

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to concrete reinforced polypropylene fibers in a timely manner. Thank you for your love of our products.

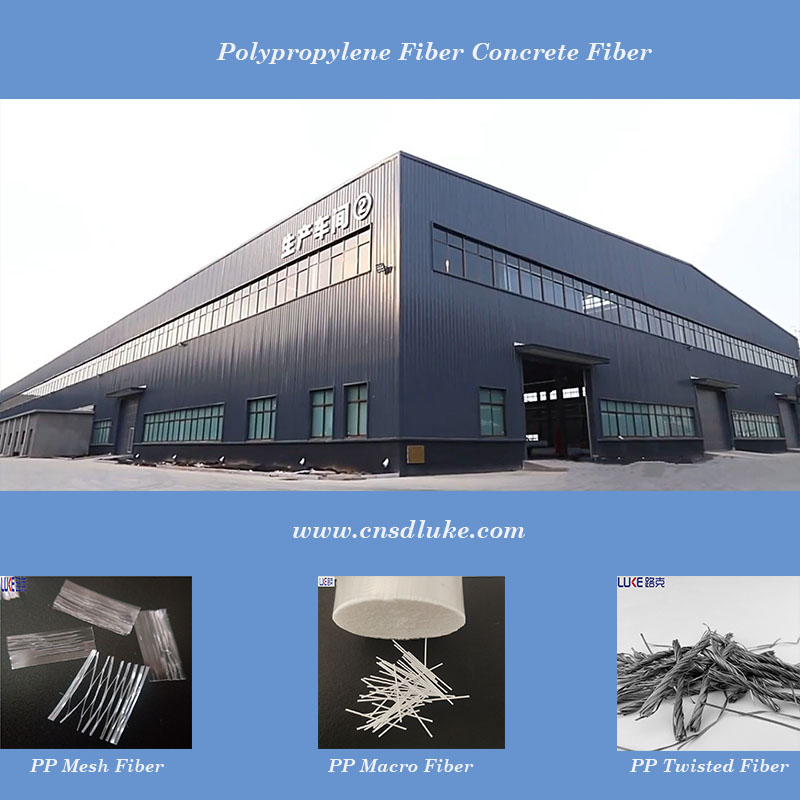

About us :

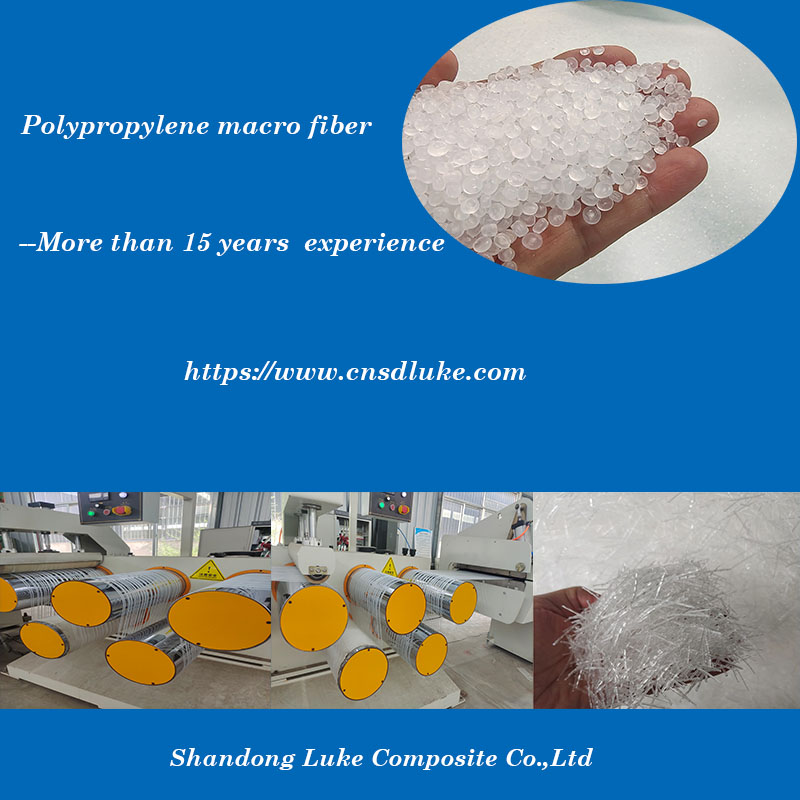

Shandong Luke composite Co.,Ltd is a professional company on production and sales engineering anti-crack fiber.Concrete anti-crack fiber series such as Polypropylene(pp) fiber、polypropylene(pp) mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle polypropylene fiber、steel fiber、basalt fiber etc.Our polypropylene fibers have been exported to more than 30 nations and regions, such as Southeast Asia, Australia, North America, Europe, Middle East and Africa.And it received unanimous praise from the customers.

The application range of polypropylene fiber is very wide,as follows:

◆Floor engineering,railway engineering.

◆Surface of road and highway.

◆Toll station, Concrete panel, Factory floor, Tunnel, Roof, basements,Parking lot and Wharf of the port.

◆Bridge project, Water conservancy project.

◆Harbour and airport runways.

◆Other engineering fields :Reinforcement concrete fiber is also used in other engineering fields, such as culvert support, mountain slope protection and other support engineering.

Polypropylene macro fiber concrete fiber production Workshop:

Professional equipment, high quality polypropylene synthetic macro fibers series products, is your best choice,welcome to our company!

If you want to know more about the more fibers ,you can continue to ask me questions.

Our company aim is :quality first! reputation first!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible