Industry News

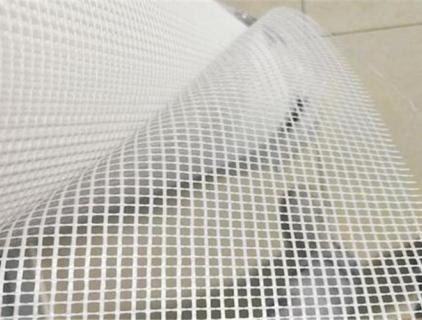

Glass fiber mesh (Fiberglass Mesh) is a new type of alkali-resistant reinforcing material made from glass fibers and coated with alkali-resistant polymer emulsion. It features high tensile strength, good alkali resistance, strong chemical stability, and excellent dimensional stability. It is widely

2026/01/23 15:22

Luke 3D erosion control mat (also called 3D geomat) is a high-performance geosynthetic material with a 3d mesh structure. It integrates soil reinforcement, erosion control and vegetation cultivation functions, solving the pain points of traditional slope protection materials (such as poor stability

2025/12/26 09:25

In the field of construction engineering, concrete cracks and lifespan degradation have long been the core pain points that have plagued the industry - cracks not only affect the aesthetic appearance of the structure, but also may cause chain problems such as leakage and corrosion, leading to a

2025/12/09 10:54

Geotextiles, as one of the core products of geotechnical synthetic materials, are widely applied in various fields such as civil engineering, environmental protection engineering, agriculture, and water conservancy due to their unique properties. The specific classification and application details

2025/12/02 16:16

In the era of green infrastructure and high-quality construction, polypropylene concrete fiber (PP fiber,PP micro fiber,pp macro fiber,pp twisted fiber) has emerged as a game-changing material, revolutionizing the durability, crack resistance, and sustainability of concrete structures worldwide.

2025/11/29 10:40

The 3D composite drainage net not only resolves the two core problems of excessive self-weight and easy blockage that exist in traditional drainage layers, but also brings new improvements in terms of construction efficiency, space saving, and total life cycle cost.And it can be customized with

2025/11/24 15:24

Different types of projects have different requirements for the long-term load, flow and durability of the 3D drainage net. When choosing the product, it is necessary to follow the regulations of the country or region where the project is located.When choosing a composite drainage geonet for

2025/11/24 10:45

Polypropylene(PP) filament fibers enhance the durability of concrete by increasing its tensile strength and dispersion. Polypropylene monofilament fibers(pp micro fibers) are a type of high-strength bundled single filament fibers, which are manufactured from 100% polypropylene through a special

2025/11/12 14:44

The role of polypropylene synthetic micro fiber in concrete crack resistance:1. The soft and lightweight polypropylene monofilament fibers in concrete compensate for the brittle nature of rigid concrete.2. Effectively solve the problems of early plastic cracks and later shrinkage cracks in concrete

2025/10/20 11:07

The drainage board with geotextile layer (usually formed by the combination of the drainage board base material and the geotextile) further enhances the core functions such as drainage, filtration, and protection through the synergy of the two materials' properties.Its advantages mainly lie in the

2025/08/21 10:22

Traditional concrete is prone to cracks when facing temperature changes and plastic shrinkage, thereby affecting the durability and safety of the structure. However, polypropylene fibers(PP micro fibers,PP macro fibers or PP mesh fibers), as concrete reinforcing fibers, can effectively address

2025/06/30 10:37

In the current era where the demand for urban rainwater management is increasing, choosing the appropriate rainwater module(rain water storage module) is of utmost importance. When selecting a rainwater module, one must consider three aspects: scene requirements, performance parameters, and cost-

2025/06/12 10:39

Submitted successfully

We will contact you as soon as possible

Close