Polypropylene Fiber for Concrete: Reduce Cracks and Extend Lifespan

In the field of construction engineering, concrete cracks and lifespan degradation have long been the core pain points that have plagued the industry - cracks not only affect the aesthetic appearance of the structure, but also may cause chain problems such as leakage and corrosion, leading to a significant increase in maintenance costs and even shortening the service life of the building. However, the emergence of polypropylene fibers (PP fibers) for concrete has become the key material to solve this problem with its "reducing 70% of cracks and extending 5 years of service life" outstanding performance, and is triggering a durability revolution in the global infrastructure sector.

The formation of concrete cracks is essentially the result of the mismatch between the shrinkage stress and the tensile strength during the hardening process. Polypropylene fibers inhibit crack formation at its root through three core mechanisms:

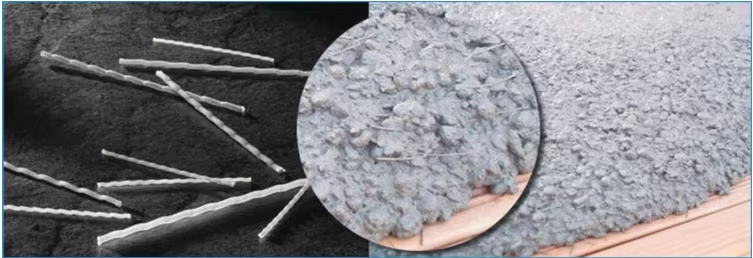

◆Three-dimensional support: The fiber diameter is 15-50 μm and the length is 6-50 mm. They are uniformly dispersed in the concrete to form a "microscopic framework", providing tensile stress support during the cement hydration shrinkage, preventing the initiation and expansion of small cracks.

◆Enhanced interface bonding: Polypropylene fibers modified with nanotechnology have a 40% increase in adhesion to the cement matrix, effectively transferring stress and avoiding the generation of cracks due to interface separation, especially suitable for large-volume concrete, thin-walled components, etc., prone to cracking.

◆Anti-seepage and anti-freezing synergy: Polypropylene fibers (pp macro fiber, pp micro fiber) fill the capillary pores in the concrete, increasing density, not only reducing crack causes, but also raising the anti-seepage grade to above P8. They remain structurally stable even under -40℃ freeze-thaw cycles or 50℃ high-temperature conditions, further reducing the risk of cracks.