Geotextile Fabric For Coastal Erosion Control

Geotextile Fabric has good high tensile strength.

Geotextiles have good resistance to aging, tear and puncture.

Geotextiles has good impermeability and resistance to deformation.

It can resistance to acid and alkali.

800g/m2 Geotextile Fabric is suit for under rocks on a shoreline

Geotextile fabric supplier offers factory direct price

Geotextile Fabric For Coastal Erosion Control

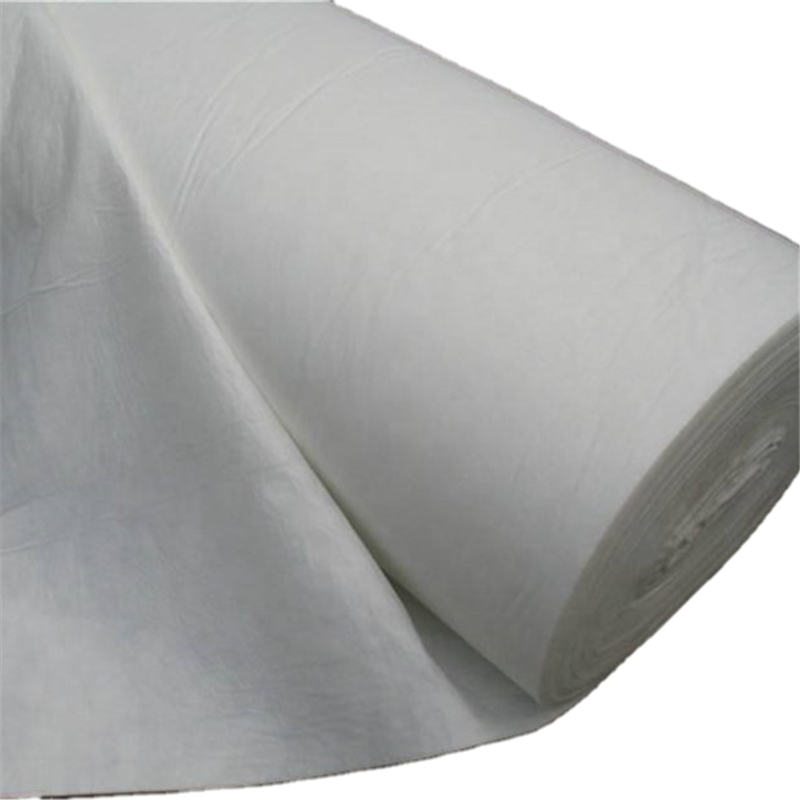

Geotextile fabrics are usually produced from polyester or polypropylene by different equipment and technology to get different thickness. And typically made in three forms; woven geotextile, needle punched geotextile, and heat bonded geotextile fabric. PP(PET)geotextiles fabrics can endure a wide range of extremities.Geotextile fabric is often used under coastal rocks (riprap) in shoreline protection and erosion control projects. Using geotextile fabric under coastal rocks enhances the longevity and effectiveness of shoreline protection measures, making it a critical component in coastal engineering projects.

The high strength geotextile fabric feature&functions:

◆Separation: Geotech fabric prevents the mixing of the underlying soil with the rock layer, maintaining the integrity and stability of the structure.

◆Filtration: It allows water to pass through while preventing soil particles from being washed away, reducing erosion.

◆Reinforcement: The application of geotextile increases the tensile strength of the soil and improving the overall stability of the coastal structures.

◆Drainage: It facilitates the flow of water, reducing hydrostatic pressure and preventing water buildup behind the rock layer.

Geotextile specification:

Name:Geotextile Fabric(Geofabric)

Width:1~6mm

Thickness:0.9mm-5mm

Weight:100g~800g/m2

Material:PP(polypropylene) or PET(Polyester)

Lead time and packaging of staple needle punched geotextiles:

Quantity(square meters) | 1-6000 | 6001-30000 | >30000 |

Lead time(days) | 2 | 5 | To be negotiated |

Woven bag in roll or customer’s requirements.

Installation tips:

◆Site Preparation: Clear the area of debris and level the ground.

◆Fabric Placement: Roll out the geotextile fabric over the prepared area, ensuring it covers the entire surface.

◆Overlap and Secure: Overlap adjacent fabric sheets by a minimum of 12 inches and secure them with stakes or pins to prevent movement.

◆Rock Placement: Carefully place the coastal rocks (riprap) over the fabric, ensuring even distribution and minimal fabric damage.

Application fields of geotextile fabric:

◆Reinforcement in retaining wall backfill

◆Strengthen the weak road and fix the cracks on the road.

◆ Improve the stability of slope and reinforcement soil,avoid water and soil loss and soil frozen in jure.

◆Isolation layer of drainage pipe or gravel sub-drain.

◆Vertical or horizontal drainage,bury in soil to release air pressure.

◆ Reinforcement the weak foundation of engineering of road,railway,embankment,airport.

About our products and our after-sales service:

Shandong Luke Composite Co., Ltd. is a professional company specializing in the production and sales of geomaterials. The company mainly produces geotextile, geomembrane, drain board,geogrid,geocell,3D geomat, drain mat drainage net, grass paver ect.Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to non-woven Geotextile,Woven Geotextile in a timely manner. Thank you for your love of our products.

our aim is quality first, credit first!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible