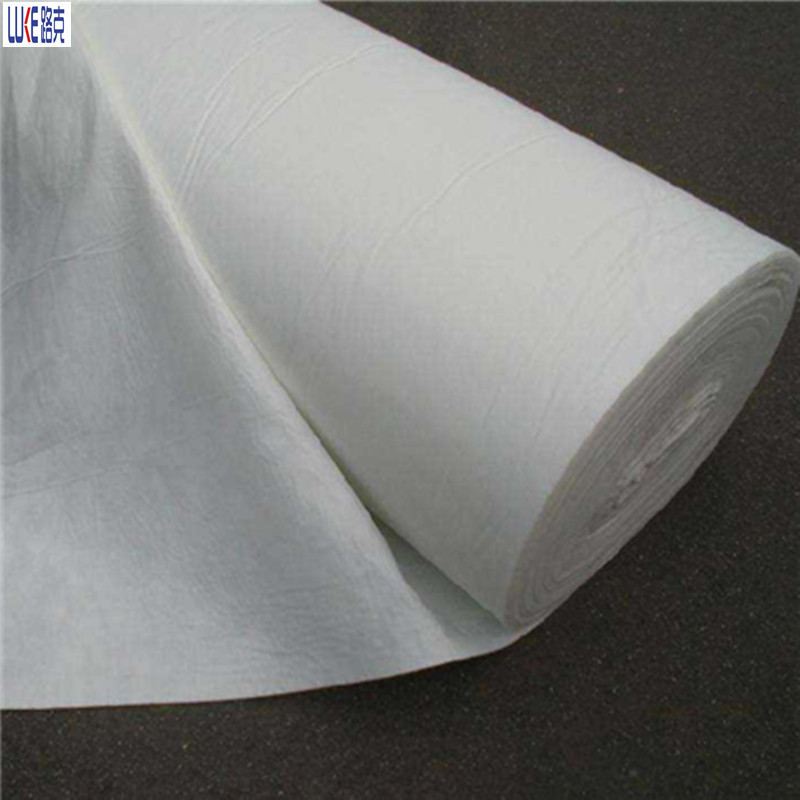

Filament Polyester Geotextile Non Woven Geotextile

100% Polyester filaments geotextile has good high tensile strength.

Filament polyester geotextile fabric have good resistance to aging, tear and puncture.

Polypropylene or polyester geotextile can resistance to acid and alkali.

Geotextiles has good impermeability and resistance to deformation.

Polyester filament geotextiles are highly durable and resistant to UV degradation, chemicals, and biological degradation, ensuring long-term performance even in harsh environmental conditions.

Filament Polyester Geotextile Non Woven Geotextile

Filament polyester geotextiles are engineered fabrics made from 100% polyester filaments, widely used in construction, environmental protection, and infrastructure projects. Below is a detailed breakdown of their features, applications, and purchasing considerations.

Polyester Geotextile fabric advantages:

◆High Tensile Strength: Filament polyester geotextiles are known for their high tensile strength, which makes them suitable for applications requiring reinforcement and stabilization, such as road construction and embankment reinforcement.

◆Durability: These geotextiles are highly durable and resistant to UV degradation, chemicals, and biological degradation, ensuring long-term performance even in harsh environmental conditions.

◆Excellent Filtration Properties: They provide effective filtration by allowing water to pass through while retaining soil particles, which helps in preventing soil erosion and maintaining the integrity of the structure.

◆Good Drainage: The structure of filament polyester geotextiles facilitates efficient drainage, reducing the risk of water accumulation and associated problems like soil saturation and structural instability.

◆Resistance to Creep: Polyester has a low creep potential, meaning it maintains its shape and strength under constant stress over time, which is crucial for long-term stability in reinforcement applications.

◆Flexibility: These geotextiles are flexible and can conform to the shape of the underlying surface, providing uniform support and stress distribution.

◆Ease of Installation: Filament polyester geotextiles are relatively easy to handle and install, which can reduce labor costs and installation time.

◆Cost-Effective: Given their durability and long service life, filament polyester geotextiles can be a cost-effective solution for many engineering projects, reducing the need for frequent replacements or repairs.

◆Environmental Benefits: By preventing soil erosion and promoting vegetation growth, these geotextiles can contribute to environmental conservation efforts.

The parameters of geotextiles:

Geotextile Type | Non-Woven Geotextile |

Type | Geotextile |

Width | 2-6m |

Application | Building Construction |

Material | PP(polypropylene)PET(polyester) |

Color | White, Black, Green |

Function | Filter, Reinforcement, Protection |

Weight | 100-800g/㎡ |

Certificate | ISO9001 |

Package | Plastic Woven Bags |

Lead time and packaging of staple needle punched geotextiles:

Quantity(square meters) | 1-6000 | 6001-30000 | >30000 |

Lead time(days) | 2 | 5 | To be negotiated |

Woven bag in roll or customer’s requirements.

Application fields of filament polyester geotextile Non-Woven geotextile

◆Infrastructure: Reinforcement of roads, railways, and airport runways to distribute loads and prevent soil mixing.

◆Landfill stabilization and erosion control in coastal dunes.

◆Geotextile used for water conservancy systems (riverbank protection, culvert lining).

◆Construction: Separation layers in foundations, slope protection, and waterproofing solutions when combined with asphalt or rubber.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible