54mm Twisted Fiber Polypropylene Fiber For Concrete

Polypropylene fiber twisted fiber in concrete has excellent crack resistance.

It can enhance mechanical properties.

The properties of raw materials are very stable.

The addition of pp twisted fiber can improve the durability of concrete, extend the service life of the structure

Strong acid and alkali resistance.

High strength: structure of polypropylene twisted fiber improves tensile properties.

Polypropylene twisted fiber has strong anti-ultraviolet function.

54mm Twisted Fiber Polypropylene Fiber For Concrete

Twisted fiber is one of our fiber series products, it is a kind of high performance fiber used in construction engineering.Polypropylene bundle twisted fiber is a substitute product developed for steel fiber. Compared with steel fiber, polypropylene bundle twisted fiber has the characteristics of acid and alkali corrosion resistance, high strength, easy dispersion, easy construction, and no damage to mixing equipment.The addition of twisted fibers in the early stage of concrete can reduces plastic shrinkage cracks during curing and reduce the dry shrinkage cracks in the later stage.

The polypropylene fiber twisted Fiber technical parameters:

Density(g/cm³) | 0.91 |

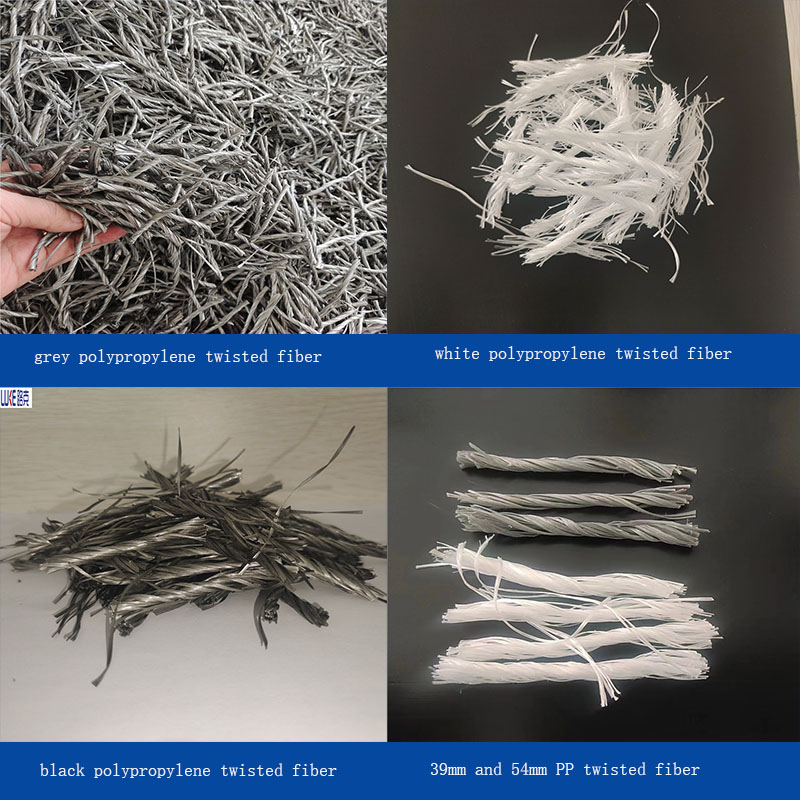

Length(mm) | 30~70 |

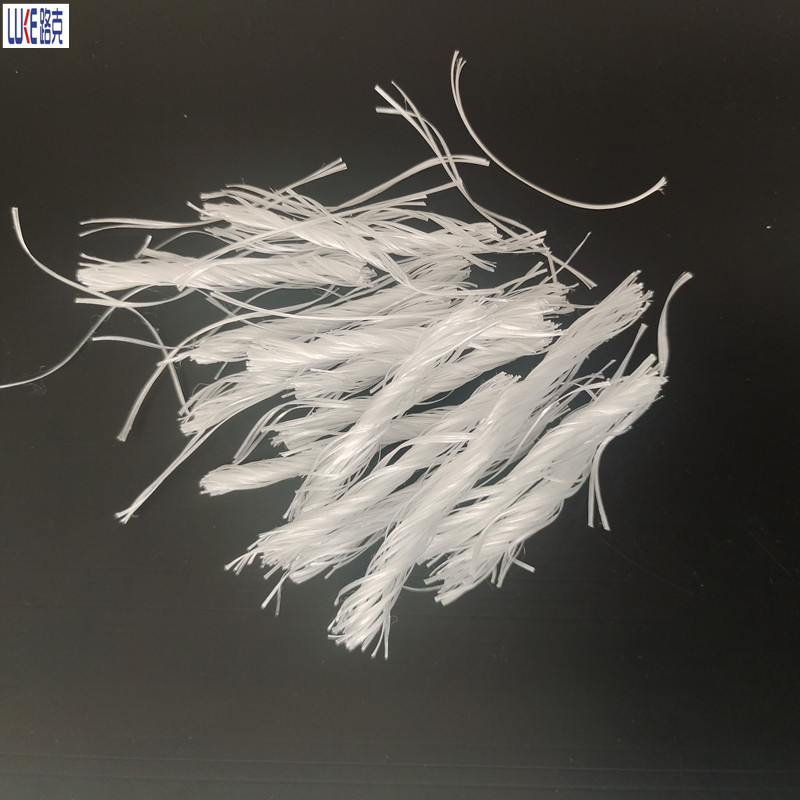

Color | White/Black/Grey |

Shape | Twisted bundle |

Tensile Strength(MPa ) | >400 |

Elastic Modulus(MPa ) | >4000 |

Equivalent Dia(mm) | 0.3±0.05 |

Crack Elongation(%) | ≥15 |

Piont | 160℃ |

Material | 100%Polypropylene |

Luke 54mm polypropylene twisted fiber advantage:

◆Good dispersion: 54mm pp fiber concrete fiber is easy to disperse in concrete and can be evenly distributed.

◆Strong gripping force: THE polypropylene fiber can be firmly attached to the concrete, enhance its crack resistance.

◆High cracking strength:Concrete pp fiber has a high cracking strength, can withstand greater stress.

◆Acid and alkali corrosion resistance:Twisted bundle polyproppylene fiber has good acid and alkali resistance.

◆High elastic modulus:It has a high elastic modulus, can resist deformation.

About us:

Shandong Luke composite Co.,Ltd is a professional company on production and sales engineering anti-crack fiber.Concrete anti-crack fiber series such as PP fiber、PP mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、bunchy form twisted pp fiber、steel fiber、basalt fiber etc.We can provide a sample of 1 kg.

Professional equipment, high quality polypropylene fibers series products, is your best choice,welcome to our company!

If you want to know more about the more fibers ,you can continue to ask me questions.

Our company aim is :Quality first!Reputation first!

Polypropylene twisted fiber packaging and transport:

Can be in woven bags, 20kg/woven bag.

Paper bags,0.9kg/paper bag, or poly bags,1kg/poly bags,pallet,or need you requirement.

Polypropylene fiber application:

Wall and roof of the tunnel and mine,dam pane,spillway,channel lining.

Road surface,bridge deck,sidewalk,ect.

Various prefabricated concrete,shotcrete,structural concrete.

Industrial workshop,ware house and parking lot,Airport runway, underground.

Hydraulic engineering and other large scale cement concrete crack resistance enhancement.

After-sales service:

Our company provides a one-stop service, and our technical staff provides 24/7 online support to solve any technical problems related to polypropylene twisted fiber concrete anti-crack fiber in a timely manner. Thank you for your love of our products.

Polypropylene twisted fiber typical dosage:

Type of engineering | Recommended dosage(kg/m) | Main role |

General crack resistance | 0.6-0.9 | Controlling plastic cracks |

Impact resistance requirement | 1.0-1.5 | Improved toughness |

Special anti-corrosion | 1.2-1.8 | Enhanced durability |

Ultra-high performance concrete | 2.0-3.0 | General enhancement |

Related Products

Related News

Submitted successfully

We will contact you as soon as possible