High Strength Polypropylene Mesh Fiber Concrete Fiber

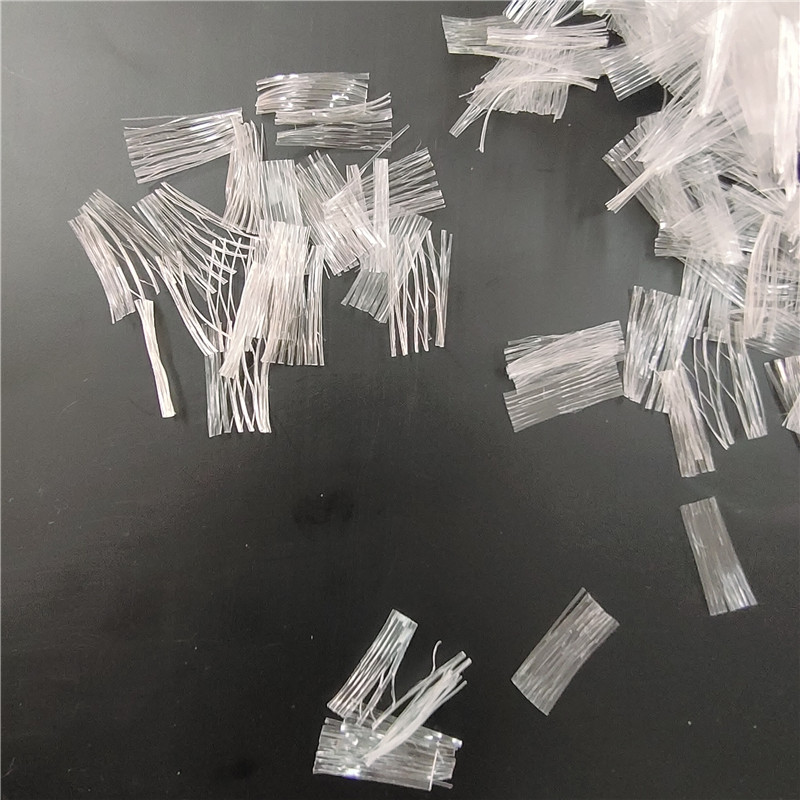

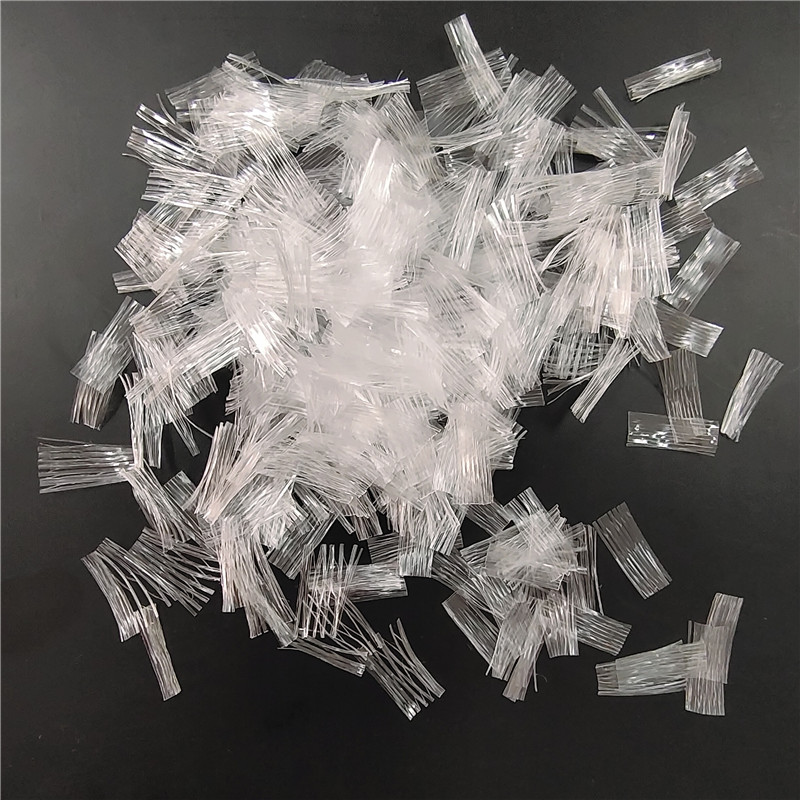

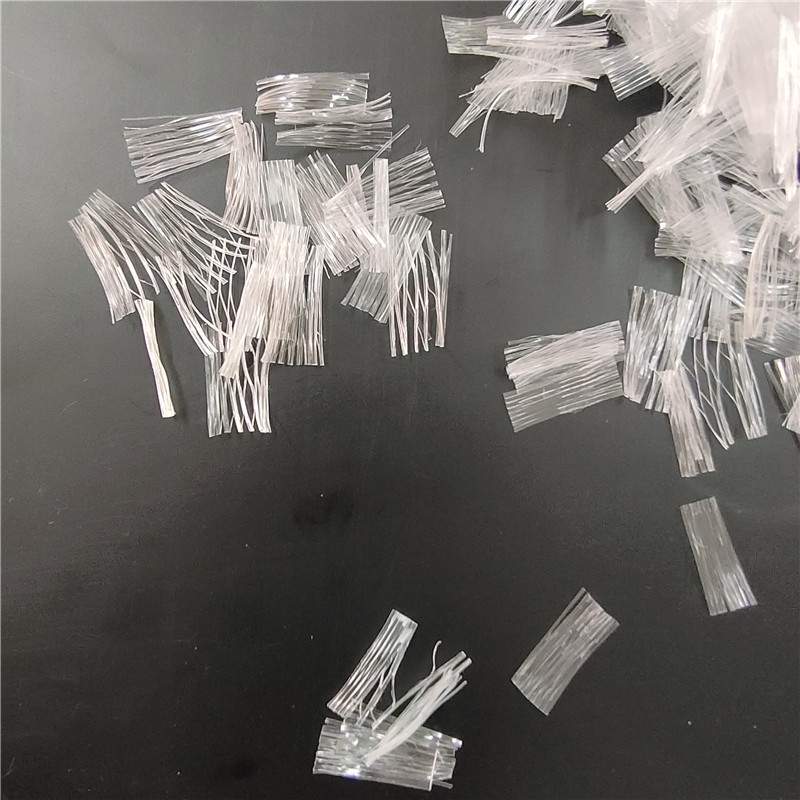

Polypropylene concrete fiber has good dispersion.

Good physical properties and stable chemical properties.

Polypropylene mesh fibers have strong wear resistance.

It has High tensile strength in concrete.

The polypropylene fiber is not easily corroded.

The optimization of o fiber length ensures better dispersion, avoids agglomeration and reduces the difficulty of stirring.

High Strength Polypropylene Mesh Fiber Concrete Fiber

High-strength concrete mesh fiber is a kind of synthetic fiber material made through a special process, mainly used to be incorporated into concrete to form a three-dimensional mesh reinforcing structure. Its "high strength" is reflected in two aspects: the tensile strength of the fiber monofilament is high: it is stronger than ordinary fibers and approaches or exceeds the performance of some steel fibers. Overall strength improvement of composite materials: By optimizing the fiber distribution and bonding performance, the crack resistance, impact resistance and durability of concrete are significantly enhanced.

High strength polypropylene mesh fiber feature:

◆It has strong crack resistance, a stronger ability to suppress micro-cracks, can reduce the early plastic shrinkage cracks in concrete, and has a higher density of fiber network nodes, effectively concentrating the dispersed force.

◆High-strength fibers absorb energy more efficiently under impact loads, and their impact resistance performance has been improved.

◆Enhanced durability: It has better resistance to acid and alkali corrosion than steel fibers, with no risk of rust, and is suitable for corrosive environments such as Marine engineering and saline-alkali land.

◆The ability to resist freeze-thaw cycles has been enhanced, extending the service life of the structure.

The optimization of o fiber length ensures better dispersion, avoids agglomeration and reduces the difficulty of stirring.

◆No additional binding or welding is required, saving labor costs.

Technical Parameter with fiber mesh for concrete reinforcement:

Product Name | |

Density(g/cm³) | 0.91 |

Length(mm) | 19、38、24 or according to your need |

Color | White |

Shape | Net-like Beam |

Tensile Strength(MPa ) | >550 |

Elastic Modulus(MPa ) | >3500 |

Equivalent Dia | 100±50 |

Crack Elongation(%) | ≥10 |

Piont | 160-170℃ |

Resistance Acid alkali | Strong |

Packing and shiping:

All polypropylene fibers products can be shipped by sea or land.

◆Common 0.9 or 1Kg per bag, 20Kg/woven bag ,may packed as customer’s requirement.

◆You can choice carton, paper bag, woven bag, paper bag or water soluble packaging, pallet

◆Special packaging can be supplied on your need.

Key points of construction:

◆Dosage control: According to the design requirements to control the polypropylene mesh fiber content, too much or too little will affect the effect.

◆Uniform dispersion: Ensure that the polypropylene fibers(mesh fibers, macro polypropylene fibers) are evenly distributed in the concrete to avoid clumping.

◆Mixing time: appropriately extend the mixing time to ensure that the fiber is evenly dispersed.

Application:

◆Polypropylene fiber can used for Concrete roads, Bridges, airport roads, factory buildings and other projects that strictly require crack resistance.

◆The walls of tunnels, mines, roofing, reservoirs and other special construction projects improve the impermeability and durability of the structure.

◆Used to enhance crack resistance and shock resistance of floors, walls, etc.

◆Prefabricated components: pipe piles, concrete slabs, to enhance crack resistance during transportation and installation.

About our company and our after sale-service:

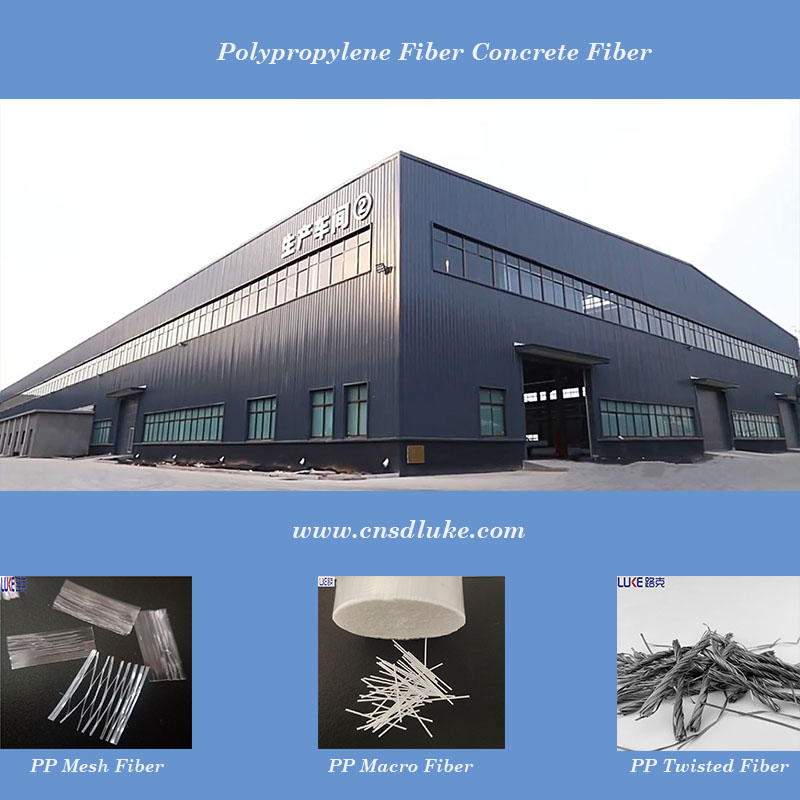

Shandong Luke composite Co., Ltd.is a professional company on production and sales engineering anti-crack fiber.Concrete anti-crack fiber series such as polypropylene(PP) fiber、polypropylene(PP) mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber、basalt fiber etc.

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to polypropylene fiber reinforced concrete fiber in a timely manner. Thank you for your love of our products.Welcome to request a quote!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible