Polypropylene Synthetic Mesh Fiber for Concrete

Polypropylene fiber mesh has good dispersion.

Good physical properties and stable chemical properties.

Polypropylene staple fiber price is good .

Polypropylene mesh fibers have strong wear resistance.

It has High tensile strength in concrete.

The polypropylene fiber is not easily corroded.

Polypropylene Synthetic Mesh Fiber for Concrete

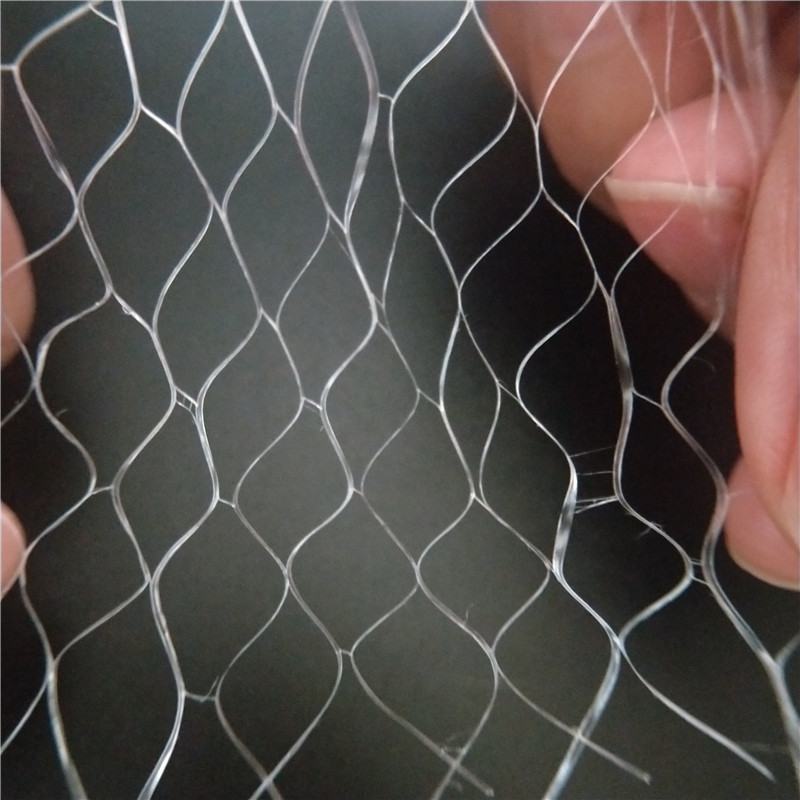

Polypropylene mesh fiber, also known as polypropylene(pp) fiber mesh, is made from polypropylene and processed through special techniques. Its appearance is a mesh structure formed by the interconnection of multiple single fibers. It is widely used in concrete.When mixed with concrete, the individual fibers or the net-like structure fully expand, forming a complex supporting system within the concrete. It can effectively control the early plastic shrinkage and settlement cracks of concrete and cement mortar.we are pp mesh fibers manufacturer,can provide factory price,and free samples.Excellent quality and strict quality inspection is your best choice.

Concrete fiber feature and function:

◆Improve crack resistance: Polypropylene mesh fibers can prevent the expansion of micro-cracks in concrete and reduce the formation of cracks.

◆Concrete polypropylene staple fiber can enhance endurance and increase service life.

◆PP mesh fiber concrete fiber can increase fire resistance.

◆Strengthen spurt & fatigue.

◆polypropylene fiber mesh can improve tensile, bending & folding strength in building engineering

◆Improve plastic deformity.

◆Strong acid & alkali resistance.

Corrosion-resistant pp mesh fiber concrete fiber technical parameters:

Product Name | PP Fiber-Mesh |

Density(g/cm³) | 0.91 |

Length(mm) | 12,19,38 |

Color | White |

Shape | Net-like Beam |

Tensile Strength(MPa ) | >450 |

Elastic Modulus(MPa ) | >3500 |

Equivalent Dia | 100±50 |

Crack Elongation(%) | ≥10 |

Piont | 160-170℃ |

Resistance Acid alkali | Strong |

Packing and shiping:

All polypropylene fibers products can be shipped by sea or land.

◆Common 0.9 or 1Kg per bag, 20Kg/woven bag ,may packed as customer’s requirement.

◆You can choice carton, paper bag, woven bag, paper bag or water soluble packaging, pallet

◆Special packaging can be supplied on your need.

Key points of construction:

◆Dosage control: According to the design requirements to control the polypropylene mesh fiber content, too much or too little will affect the effect.

◆Uniform dispersion: Ensure that the polypropylene fibers(mesh fibers, macro polypropylene fibers) are evenly distributed in the concrete to avoid clumping.

◆Mixing time: appropriately extend the mixing time to ensure that the fiber is evenly dispersed.

Application:

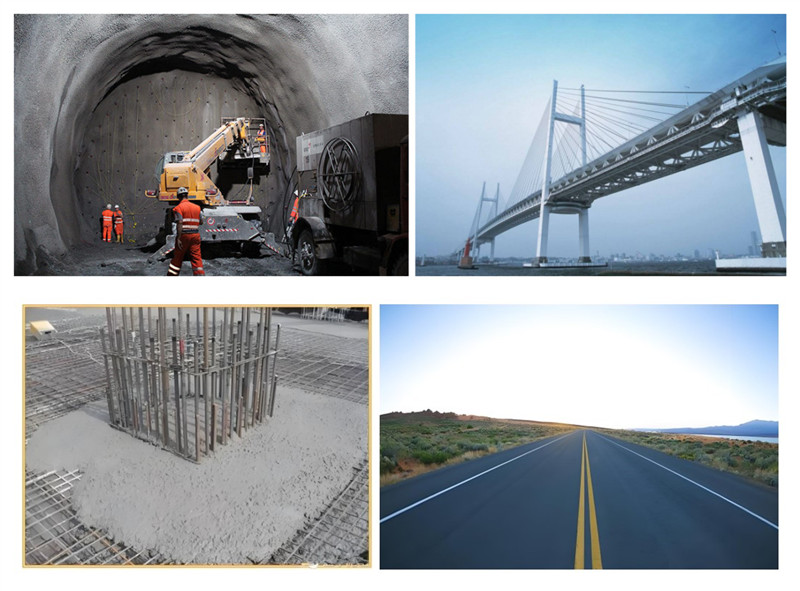

◆Polypropylene mesh fiber can used for Concrete roads, Bridges, airport roads, factory buildings and other projects that strictly require crack resistance.

◆The walls of tunnels, mines, roofing, reservoirs and other special construction projects improve the impermeability and durability of the structure.

◆Used to enhance crack resistance and shock resistance of floors, walls, etc.

About our company and our after sale-service:

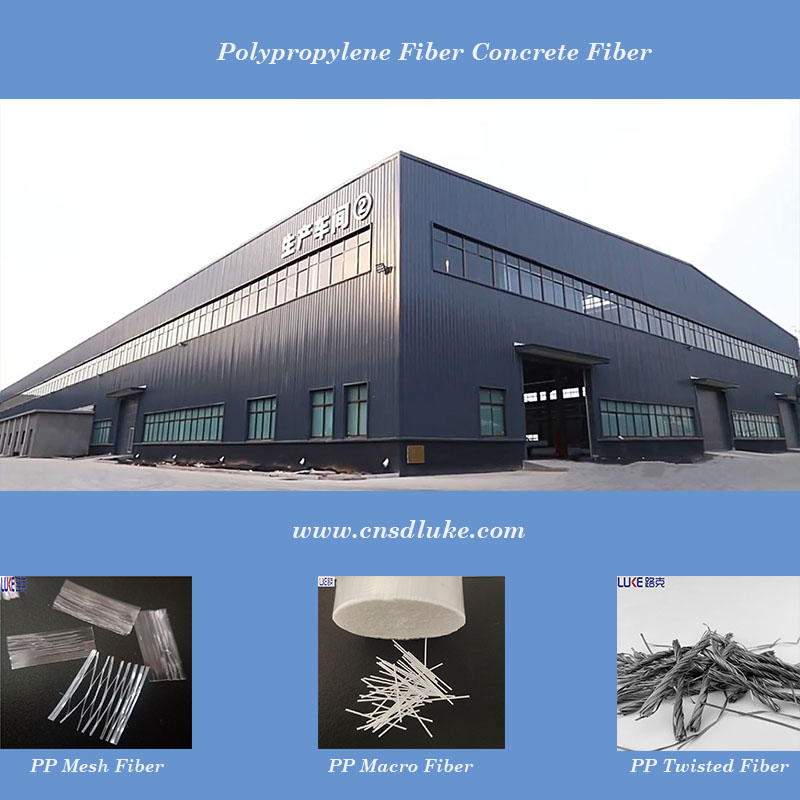

Shandong Luke composite Co., Ltd.is a professional company on production and sales engineering anti-crack fiber.Concrete anti-crack fiber series such as PP fiber、PP mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber、basalt fiber etc.

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to polypropylene fiber reinforced concrete fiber in a timely manner. Thank you for your love of our products.Welcome to request a quote!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible