100% pure Polypropylene Fiber Mesh Fiber For Concrete

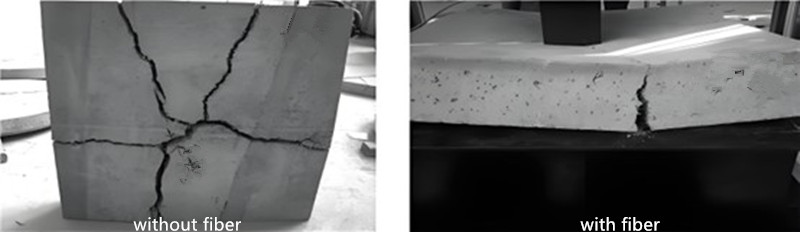

Crack Resistance: Effectively controls micro-cracks caused by temperature changes, plastic shrinkage, and drying shrinkage.

Easy Dispersion: Excellent dispersion properties ensure uniform distribution in concrete, enhancing overall performance.

Good Durability: High tensile strength and resistance to environmental factors extend the lifespan of concrete structures.

100% polypropylene fiber concrete fiber,economic benefits long service life.

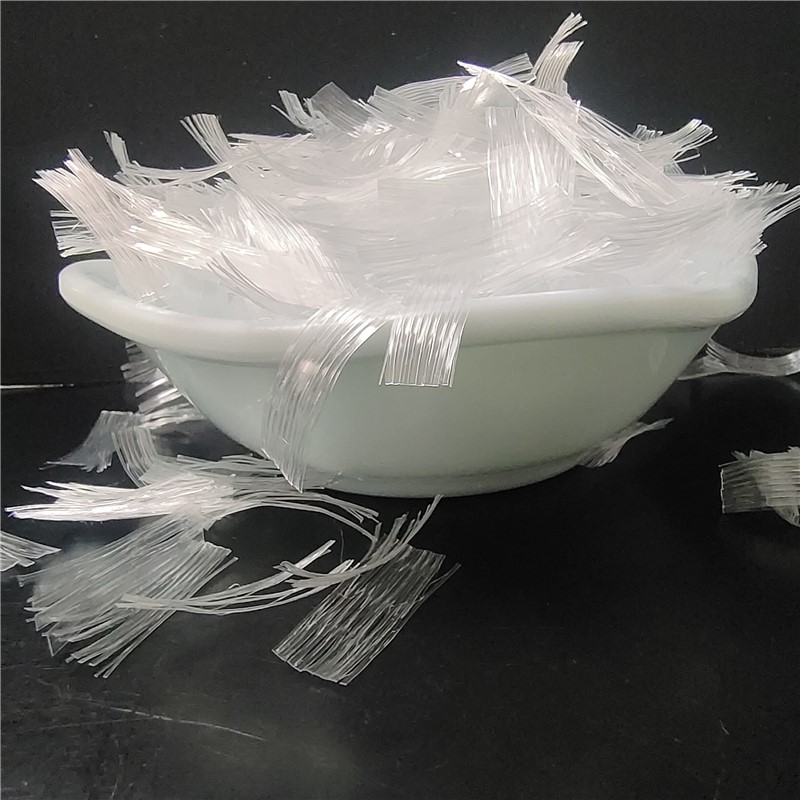

100% Pure Polypropylene Fiber Mesh Fiber For Concrete

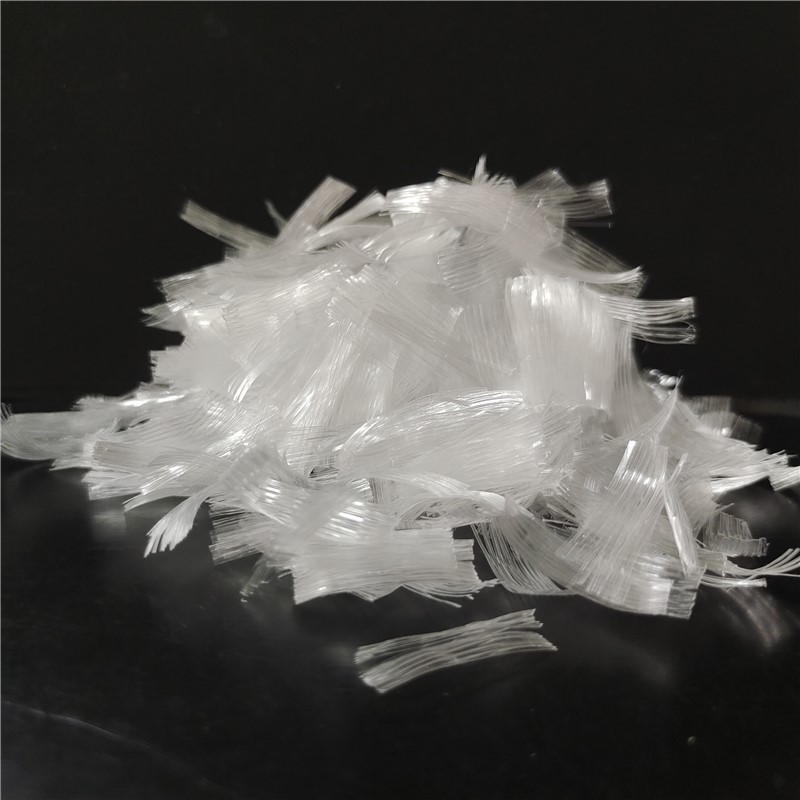

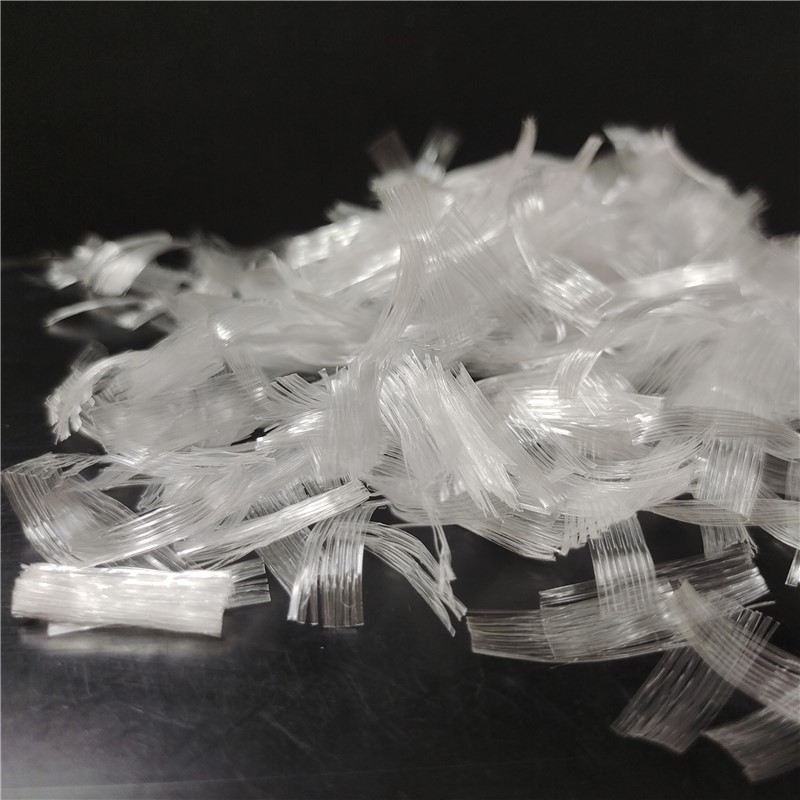

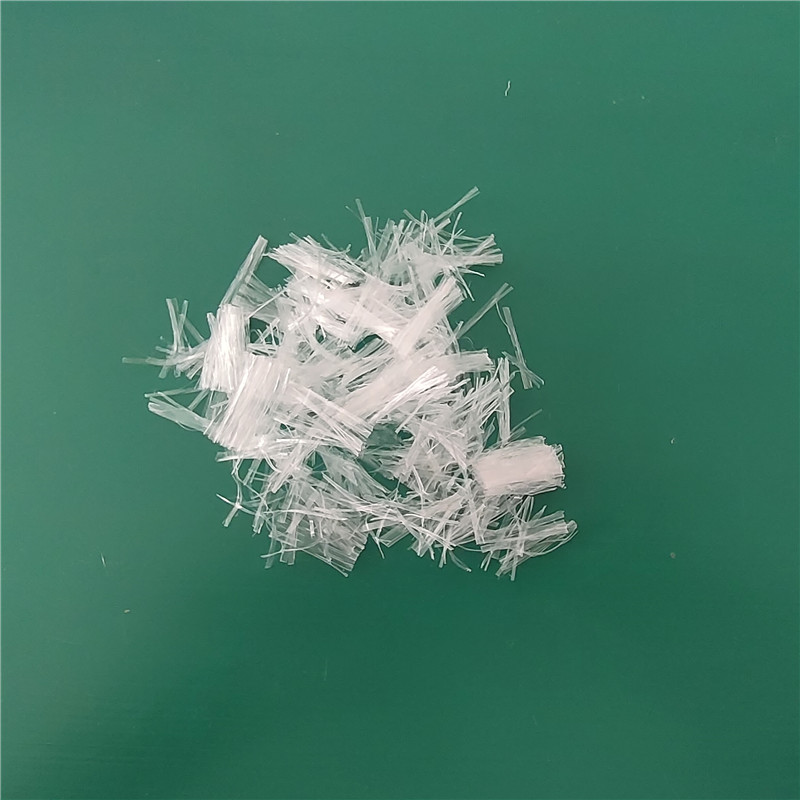

Polypropylene fiber for concrete mesh fiber with 100% polypropylene as its raw material,fiber mesh is produced by special technology.It appears netlike structure with many monofilaments connected.100% pure polypropylene fiber is commonly used as a reinforcement material in concrete to improve its performance.When used in concrete mesh fiber applications,polypropylene fibers offer several benefits:

◆As crack control polypropylene fibers help reduce plastic shrinkage cracks that occur during the initial curing phased of concrete.

◆Polypropylene concrete fiber enhance the toughness and impact resistance of concrete.

◆It can corrosion resistance,unlike steel fibers,polypropylene fibers do not corrode,thus it making them ideal for harsh environments.

◆Lightweight,polypropylene fibers are light and easy to mix into concrete without significantly changing the density of concrete.

◆Add into the polypropylene fibers can improve the cohesion of the concrete mix,reducing segregation.

Technical specification of Polypropylene Fiber (PP Mesh Fibers):

Product Name | PP Fiber-Mesh |

Density(g/cm³) | 0.91 |

Length(mm) | 12~39 |

Color | White |

Shape | Net-like Beam |

Tensile Strength(MPa ) | >400 |

Elastic Modulus(MPa ) | >3500 |

Equivalent Dia | 100±50 |

Crack Elongation(%) | ≥15 |

Piont | 160-170℃ |

Resistance Acid alkali | Strong |

Polypropylene fiber mesh concrete fiber function:

◆Improve the impermeability of concrete

◆Improve the cracking resistance of concrete

◆Improve the impact resistance and fatigue resistance of concrete

◆Improve the wear resistance of concrete

◆Improve the plastic deformation ability of concrete

◆Strong acid and alkali resistance, with good stability

◆Improving the homogeneity of concrete

Applying instruction:

◆The choices of polypropylene pp fiber mesh length:Generally,the length of polypropylene pp mesh fiber in engineering concrete is 20mm.

◆The amount of polypropylene mesh fiber is 0.9KG, and the amount of waterproof layer on the bridge floor is 1.8KG, and the amount of other materials is not changed. When there are special uses, the amount of polypropylene mesh fiber can be determined by testing.

◆Mixing process:crusted stones,fibers and sands are put into the mixer in succession.After stirring for two minutes,fiber will fully spread and then add cement and water and stir normally.The addition of materials also can be put into as usual,but the stirring time should be properly prolonged to more than 4 minutes make fiber completely mixed.

◆Mixer:Horizontal Two-shaft Forced Mixer.

Polypropylene fiber mesh packaging:

1、Typically packed in 600g or 900g bags,may packed as customer’s requirement.

2、You can choice carton, paper, bag, woven bag, paper bag, pallet.

3、Special packaging can be supplied on your need.

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to polypropylene synthetic fiber concrete fiber in a timely manner. And we can provide a sample of 1kg.Thank you for your love of our products.

About us:

Shandong Luke composite Co., Ltd is a professional company on production and sales engineering anti-crack fiber.Concrete anti-crack fiber series such as PP fiber、PP mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber etc.

Professional equipment, high quality polypropylene fibers series products, is your best choice,welcome to our company!

If you want to know more about the more concrete fiber polypropylene mesh fibers ,you can continue to ask me questions.

Our company aim is:Quality first!Reputation first!

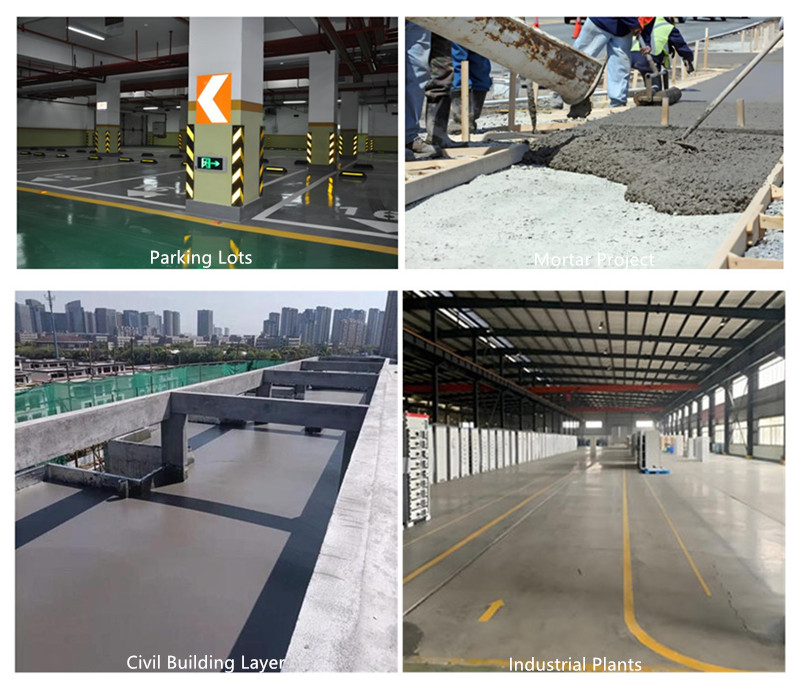

Polypropylene fibers pp mesh fiber application:

Shotcrete: Used in tunnels, slopes, and pools.

Slabs and Floors: Reduces cracking and improves durability.

Precast Concrete: Enhances the performance of precast elements.

Pavements and Roads:Improves resistance to wear and tear.

Industrial Floors: Provides better impact and abrasion resistance.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible