High Performance Polypropylene Synthetic Macro Fiber

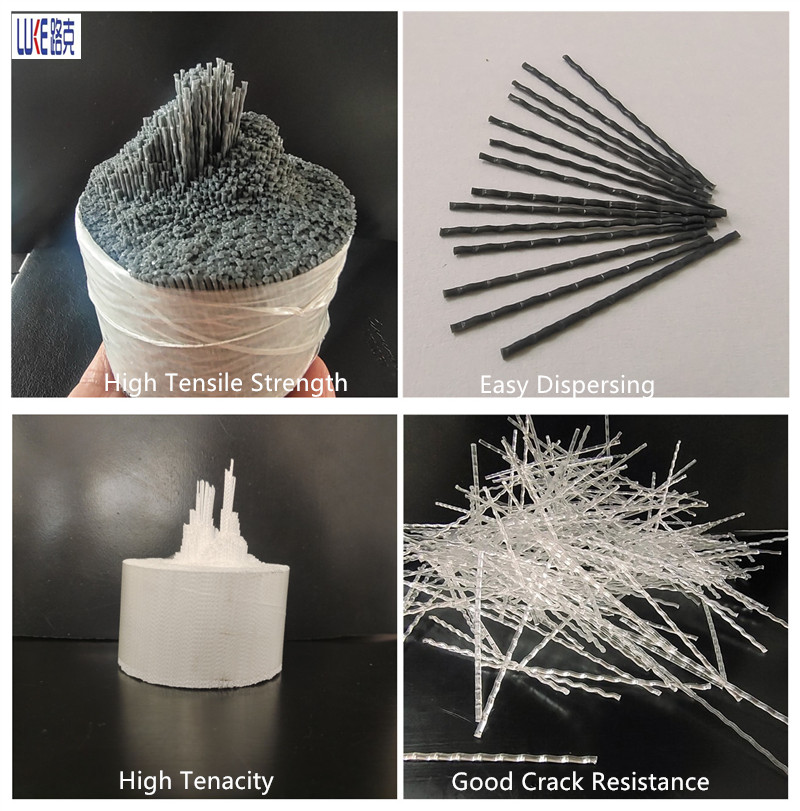

Polypropylene synthetic fibers have high tensile strength.

PP synthetic fibers in concrete can increase seepage resistance.

It has good combination and good high tenacity.

It can increase the crack resistance with in concrete.

It has strong acid and alkali resistant.

We offer factory direct sales and the synthetic fiber price is very favorable.

High Performance Polypropylene Synthetic Macro Fiber

Adding high-performance polypropylene fibers to concrete can provide excellent crack resistance, impact resistance, fatigue resistance, shrinkage control and ductility. Compared with steel fibers, it is more cost-effective, easier to construct and safer to handle. It can be used in highly corrosive environments. The surface is treated with embossing, which significantly enhances the adhesion between the fibers and the concrete, and simultaneously improves the resistance to shrinkage and cracking. In practical applications, it is necessary to combine with design requirements and select the appropriate polypropylene synthetic macro fibers.

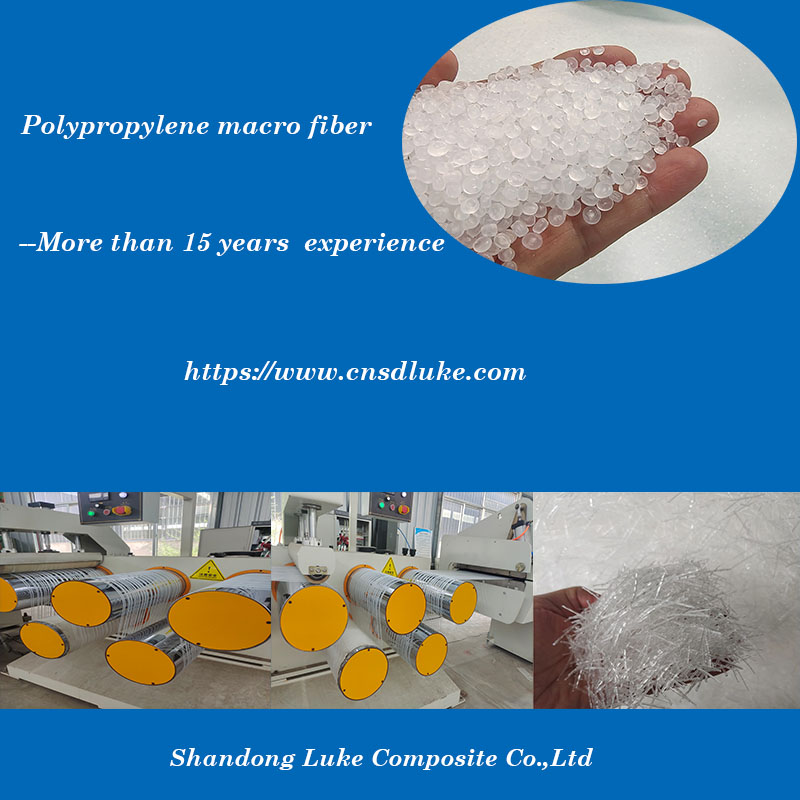

Technical parameter of polypropylene macro synthetic fiber:

Raw Materia | 100%Polypropylene | Length(mm) | 20~70 |

Trademark | LUKE | Tensile Strength | >550(MPa) |

Origin | China | Elastic Modulus | ≥4000(MPa) |

Shape | Curved,Embossed, Waved | Equivalent Dia | 0.9±0.2 |

Density(g/cm³) | 0.91 | Crack Elongation | ≥15% |

Color | White,Black,Grey | Melting Point | 160-170℃ |

Resistance Acid alkali | Strong | ||

High performance polypropylene macro synthetic fiber feature:

◆Light weight, easy to disperse

◆Enhance strength, toughness and strength.

◆Improve the durability of concrete.

◆It can reduce the leakage of concrete.

◆Polypropylene macro fiber synthetic fiber protect steel from corrosion.

◆Polypropylene fibers in concrete can improve the durability of concrete structures.

Five advantages of polypropylene fiber:

Strong crack resistance: reduce concrete plastic shrinkage cracks.

Corrosion resistance: more suitable for wet, saline-alkali environment than steel fiber.

Convenient construction: no need to worry about puncture wounds or equipment wear like steel fibers.

Economy: The cost is lower than steel fiber, especially suitable for large areas of the floor.

Environmentally friendly: Recyclable, in line with green building trends.

Polypropylene fibers packaging and delivery:

You can choice the packaging of carton,woven bag,paper bag or water soluble,pallet.

Plastic packing:1kg pp fibers/plastic bag,20kgs/PP woven bag.840kg/pallet

Paper packing:600-900g/paper bag,5kgs/carton.

Special packaging can be supplied on your request.

Please contact with us for latest price, thank you.

Customer feedback about polypropylene fiber concrete fiber:

A good product, a customer recognition, this is our greatest success, thank you for our recognition, we will continue to work hard to improve the quality of service.

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to concrete reinforced polypropylene fibers in a timely manner. Thank you for your love of our products.

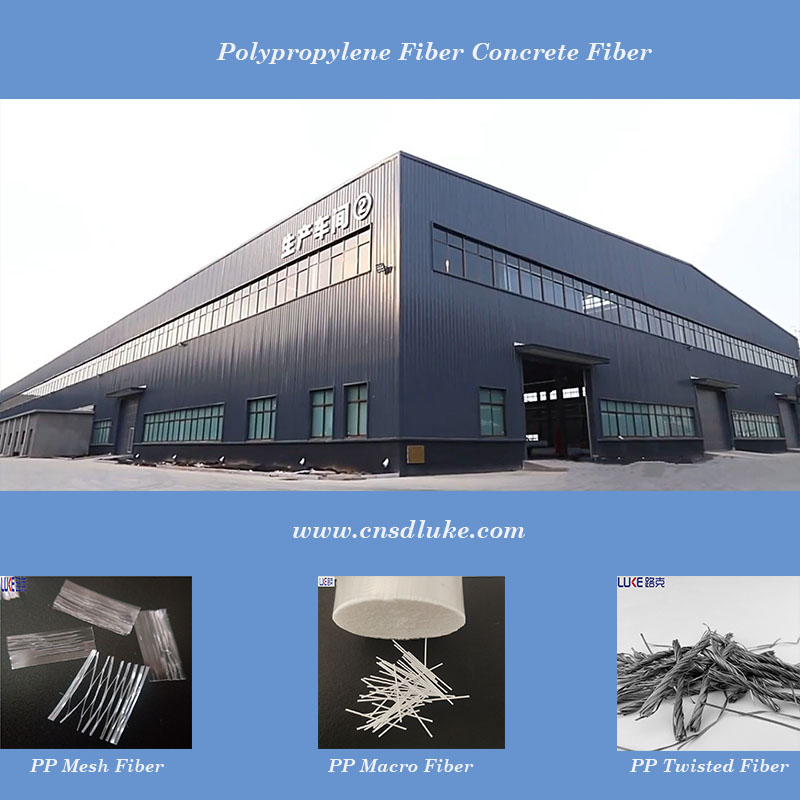

About us:

Shandong Luke composite Co.,Ltd is a professional company on production and sales engineering anti-crack fiber.Concrete anti-crack fiber series such as Polypropylene(pp) fiber、polypropylene(pp) mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle polypropylene fiber、steel fiber、basalt fiber etc.Our polypropylene fibers have been exported to more than 30 nations and regions, such as Southeast Asia, Australia, North America, Europe, Middle East and Africa.And it received unanimous praise from the customers.

The application range of polypropylene fiber is very wide,as follows:

◆Floor engineering,railway engineering.

◆Surface of road and highway.

◆Toll station, Concrete panel, Factory floor, Tunnel, Roof, basements,Parking lot and Wharf of the port.

◆Bridge project, Water conservancy project.

◆Harbour and airport runways.

◆Other engineering fields :Reinforcement concrete fiber is also used in other engineering fields, such as culvert support, mountain slope protection and other support engineering.

Polypropylene macro synthetic fiber production:

Professional equipment, high quality polypropylene fibers series products, is your best choice,welcome to our company!

If you want to know more about the more fibers ,you can continue to ask me questions.

Our company aim is :quality first! reputation first!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible