PP Macro Synthetic Fiber Helps In Various Construction Projects

Recently, polypropylene synthetic macro fiber for concrete have gained significant attention in the engineering field due to their outstanding performance. These fibers are made from synthetic resins through special processes and surface treatments, featuring high tensile strength, good dispersion, and strong adhesion.

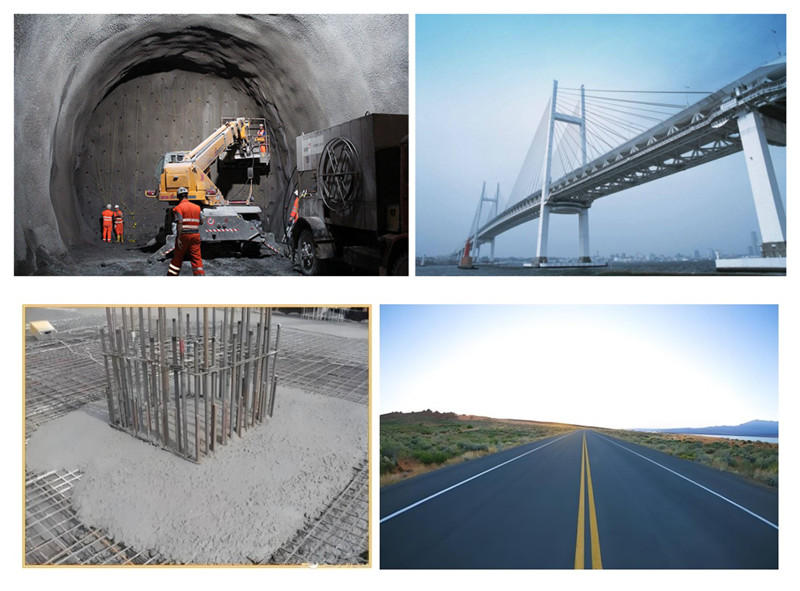

In construction projects, they can effectively reduce concrete cracks, enhance tensile, flexural, and compressive strength, improve structural durability, and protect steel bars from corrosion. For instance, in the foundation construction of high-rise buildings, concrete containing steel-like fibers can withstand greater pressure, ensuring the stability of the building.

In road and bridge engineering, pp macro synthetic fibers prove their worth. They can increase the wear resistance of concrete, make the road surface smoother, and prevent tire damage. In bridge construction, they can enhance the fatigue resistance of concrete, cope with the dynamic loads from frequent vehicle traffic, and reduce damage in the event of earthquakes and other disasters.

In water conservancy projects, PP macro synthetic fiber are also indispensable. They can reduce internal defects in concrete, enhance its impermeability, and are suitable for facilities such as reservoirs and dams, ensuring the safety of the projects under long-term water flow impact. With technological advancements, polypropylene macro fibers are continuously expanding their application boundaries, providing better material options for various construction projects.

In the construction of a large-scale cross-sea bridge, facing complex environments such as strong winds, wave erosion, and heavy traffic, traditional concrete could not meet the long-term usage requirements. The construction team innovatively used synthetic macro fibers structural pp fiebrs reinforce concrete, effectively solving the engineering problems.