Luke Staple Fiber Needle Punched Geotextile

◆Needle punched staple fiber nonwoven geotextile integrates multiple functions and possesses five core functions: filtration, drainage, isolation, protection, and reinforcement.

◆It can be adapted to various scenarios.

◆The construction efficiency is high.

◆It has strong deformation adaptability.

◆The cost is low and the service life is long.

Luke Staple Fiber Needle Punched Geotextile

Short fiber needle punched geotextile is the best material for engineering applications that balance practicality and economy.It is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness.The nonwoven needle punched staple fiber geotextile material is soft in texture and lightweight. It can be cut and spliced at will, and no complex equipment is required during installation. It adheres well to irregular interfaces and does not shift easily. The soil undergoes flexible stretching without breaking, ensuring the long-term stability of the project.

Nonwoven geotextile fabric features:

◆Stable structure, breathable and water-permeable

◆With excellent tensile strength and tear resistance strength

◆The permeable short-fiber geotextile has excellent filtering capabilities.

◆Has good flexibility and conforms to uneven surfaces.

◆It has a good isolation effect and strong acid and alkali resistance.

◆Separation: Keeps different soil layers or materials (soil and gravel) from mixing.

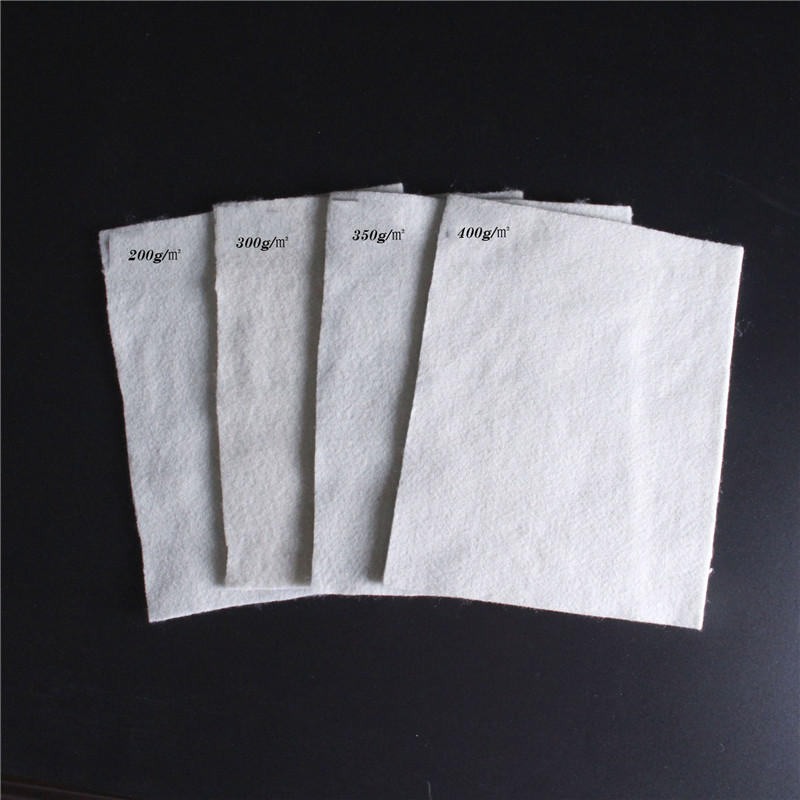

Geotextile specification:

Name:non-woven Geotextile Filter Fabric

Width:1~6mm

Thickness:0.9mm-5mm

Weight:100g~800g/m2

Material:PP(polypropylene) or PET(Polyester)

PP or Pet needle punched geotextile fabric packaging and transport:

Geotextile is one of the new materials geosynthetic materials, the general width is 4-6 meters, the length is 50-100 meters.

Woven bag in roll or customer's requirements

Geotextile fabric installation tips:

Prep: Clear debris, level soil.

Overlap: 6–12 inches between rolls to prevent gaps.

Secure: Use landscape stakes or staples.

Cover: Add mulch/gravel to protect from UV exposure.

Road construction staple fiber geotextile Road construction staple fiber geotextile

About our products and our geotextile workshop production line:

Shandong Luke Composite Co., Ltd. is a professional company specializing in the production and sales of geomaterials. The company mainly produces staple fiber needle punched geotextile, hdpe geomembrane,hdpe dimple drain board,composite drainage board,geogrid,geocell,3D geomat, drain mat drainage net, rainwater collection module etc.

After-sales service

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to geotextile fabric in a timely manner. Thank you for your love of our products.

our aim is quality first, credit first!

Geotextile Fabric application:

The application of PP(PET) needle punched geotextile is very wide, suitable for water conservancy, embankment, highway, railway roadbed, bridge, port, tunnel, airport and so on.

◆Reinforcement in retaining wall backfill

◆Strengthen the weak road and fix the cracks on the road

◆As the protective layer and filtration layer of the landfill's impermeable system, it isolates the landfill leachate from the soil, prevents groundwater pollution, and guides the leachate to be discharged.

◆Used for the anti-filter layer and drainage layer of the embankment, it prevents soil particles from penetrating with the water flow, avoids pipe seepage of the embankment, and enhances the stability of the anti-seepage system.

◆Geotextile fabric is laid between the roadbed and the pavement, separating the sand and stone materials from the soil, preventing the roadbed from sinking, while accelerating drainage, enhancing the stability of the roadbed, and is suitable for highways, municipal roads, rural roads, etc.

Erosion control staple fiber geotextile Landfill liner geotextile

Soil stabilization needle punched geotextile Drainage geotextile for foundation

Related Products

Related News

Submitted successfully

We will contact you as soon as possible