200g/㎡ Geotextile Fabric For Driveways Geotextile

Cost-effective compared to traditional drainage methods.

Long-lasting and resistant to environmental stressors.

Improves the lifespan and performance of drainage systems.

High temperature resistance, freezing resistance, aging resistance, corrosion resistance.

It is convenient for transportation, laying and construction。

200g/㎡ Geotextile Fabric For Driveways

Geotextile, also known as geotextile fabric, is a water-permeable geosynthetic material made of synthetic fibers by needling or weaving.Geotextiles are divided into woven geotextiles and non-woven geotextiles . Geotextile has excellent filtration, isolation, reinforcement and protection.

The specification of geotextile refers to its weight and density, and different specifications are suitable for different construction environments and engineering requirements. According to the standard, the weight index of geotextile is gram/square meter (g/m2), and the common specifications are :100g/㎡-800g/㎡

High performance wowen geotextiles and nonwoven geotextiles:

◆ Filtration: Prevents soil particles from clogging drainage systems while allowing water to pass through.

◆Durability: Resistant to UV rays, chemicals, and biological degradation.

◆Separation: Keeps different soil layers or materials (soil and gravel) from mixing.

◆ Flexibility: Conforms to uneven surfaces and accommodates ground movement.

◆Drainage: Facilitates lateral water flow, reducing hydrostatic pressure.

◆Protection: Shields waterproof membranes or surfaces from punctures and abrasion.

Geotextile specification:

Name:non-woven Geotextile Filter Fabric

Width:1~6mm

Thickness:0.9mm-5mm

Weight:100g~800g/m2

Material:PP(polypropylene) or PET(Polyester)

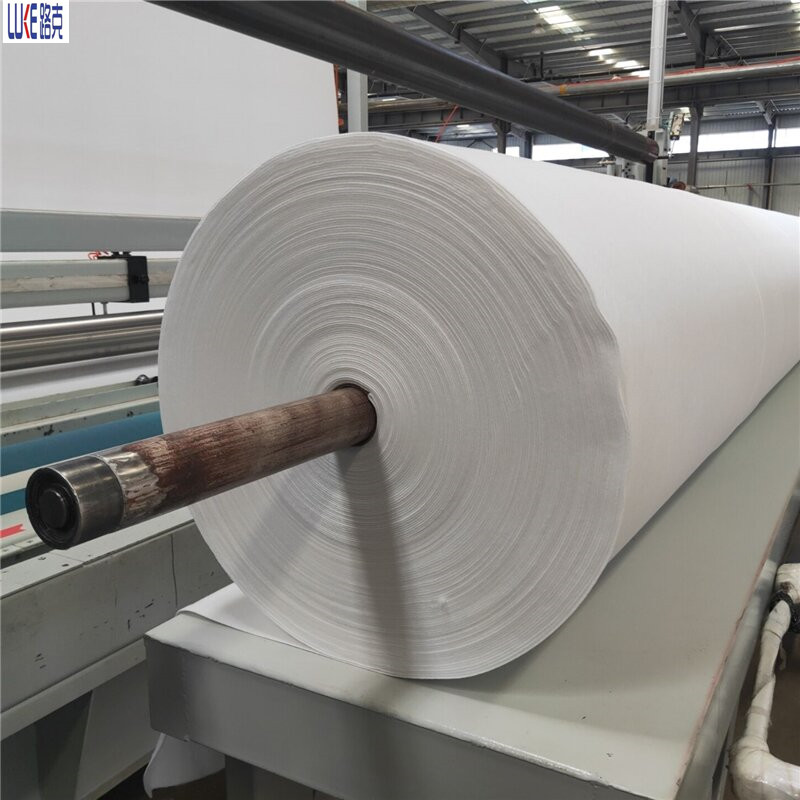

Lead time and packaging of geotextiles:

Quantity(square meters) | 1-6000 | 6001-50000 | >50000 |

Lead time(days) | 3 | 10 | To be negotiated |

Woven bag in roll or customer’s requirements.

Common specifications of geotextiles for driveways:

◆100g/m2-200g/m2 is suitable for general road moisturizing maintenance, and has a good protective effect.

◆200g/m2-300g/m2 is suitable for harsher environments and can better withstand external shocks and damage.

◆More than 300g/m2 is suitable for road protection under special circumstances, with high tensile strength and protective performance.

Installation Considerations:

◆Overlap Seams:Minimum 12-18 inch overlap to ensure continuity.

◆Securing: Use stakes or pins to prevent displacement.

◆Orientation:Place the permeable side toward the drainage source.

Application of geotextile filter fabric:

Geotextile fabric for roads construction: Stabilizes substrates and prevents aggregate sinking into soft soils.

Drainage systems: Used in French drains, retaining walls, and landfills to enhance water flow.

Erosion control: Protects slopes and riverbanks via products like silt fences.

Landscaping: Acts as a weed barrier while permitting water permeability.

About our products and our after-sales service:

Shandong Luke Composite Co., Ltd. is a professional company specializing in the production and sales of geomaterials. The company mainly produces geotextile, geomembrane, drain board,geogrid,geocell,3D geomat, drain mat drainage net, grass paver ect.Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to non-woven geotextile in a timely manner. Thank you for your love of our products.

our aim is quality first, credit first!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible