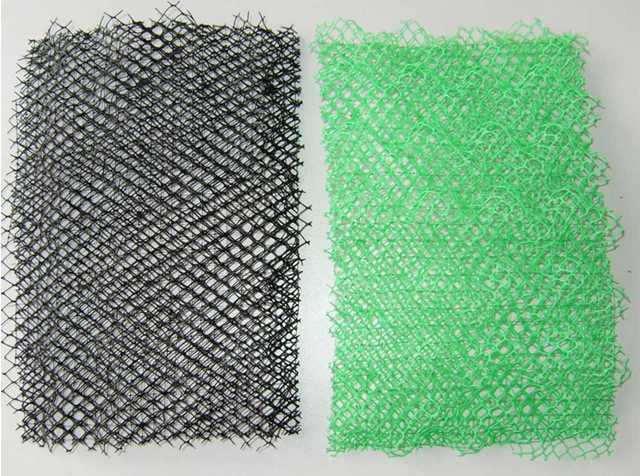

Black Reinforced Geomat

High Tensile Strength

Good for slope protection

Flexible and durable

UV resistance

Black Reinforced Geomat

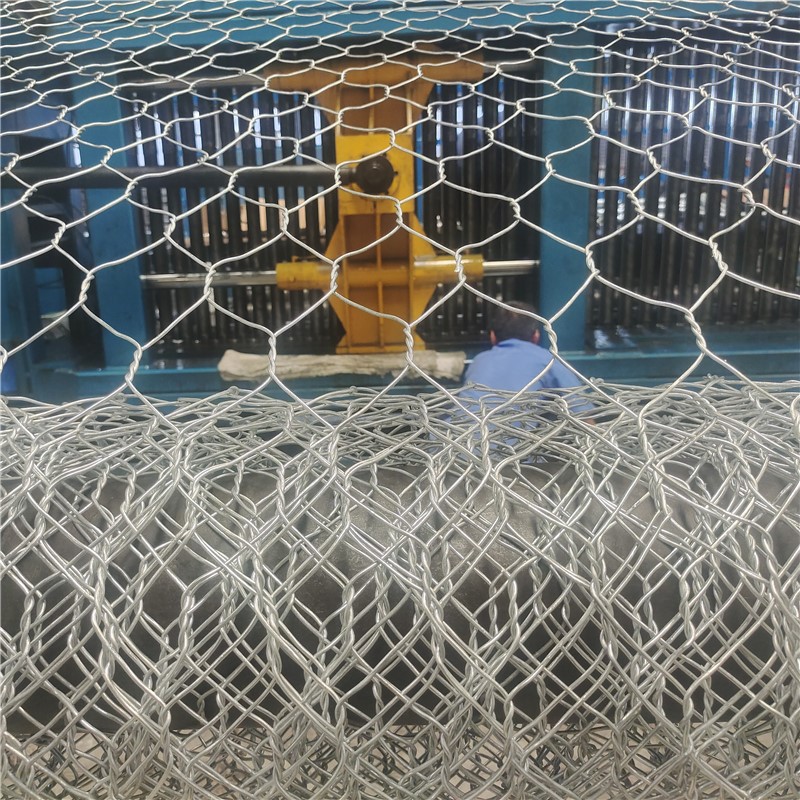

The steel wires of the 3D reinforced mesh pad are usually made of low-carbon steel wires, with diameters ranging from 2.0 to 4.0 millimeters. These steel wires have high strength and high ductility. Through the galvanizing process, a zinc layer is formed on the surface of the steel wires, which can effectively prevent the steel wires from rusting and corroding, thereby extending their service life. It has high strength and excellent corrosion resistance.

Parameter

Reinforce layer tech data | Material | Unit | pp | pp | Standard |

Weight | g/m2 | 500±50 | 500±50 | EN ISO 965 | |

Melting Point | •c | 150 | 150 | — | |

Density | g/cm5 | 0.91 | 0.91 | 一 | |

Mat wire diameter | mm | 0.55±5% | 0.55±5% | EN ISO 9863 | |

Open index | % | >90 | >90 | — | |

Mat tensile strength | Kn/m | 1.6 | 1.6 | EN ISO 10319 | |

uv | 5OOhours | ≥80% | ≥80% | ASTM D 4533 | |

Hot dipped galvanized wire mesh | |||||

Wire mesh | Mesh size | cm | 6*8 | 6*8 | — |

Steel wire diameter | mm | 22 | 2.7 | EN 10223-3 | |

Galfan weight | g/m2 | & 230 | M230 | EN 10244-2 | |

Reinforce side slop protect and erosion control mat | Breaking tensile strength | Kn/m | ≥35 | ≥50 | EN ISO 10319 |

Peel strength | N/cm | ≥6 | ≥46 | EN ISO 10319 | |

CBR punch strength | N | ≥250 | ≥250 | ASTM D 6421 | |

Thickness (2KPa) | mm | 12 | 12 | EN 964 | |

Water flow | /(mxs) | 06 (200kpa) | 0 6 (200kpa) | EN ISO 12958 | |

Tc<al weight per m2 | g/m2 | 1680±200 | 3000±500 | EN ISO 9684 | |

Color | — | Black, green, any color | |||

Roll Length | m | 2 | |||

Roll Width | m | 50 | |||

Feature

* High Tear Strength

* Flexible and durable

* Excellent Creep Resistance

* UV resistance

* Cost effective

* Increased pull-out resistance and compound strength

Application

It can be widely used to Road bed, Rail way, Slope protection, Sea coast protection & erosion control and channel.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible