High Strength Polypropylene Monofilament Fiber for Road Concrete

PP micro fiber can uniformly dispersed in concrete or mortar

Decreases construction time and labor

Can enhance the toughness and impact resistance of concrete

PP micro fiber can improve the seepage prevention and anti-seepage performance of concrete

PP synthetic micro fiber can prevent the development of microcracks

Factory price,reasonably priced

With the ASTM international standards

High Strength Polypropylene Monofilament Fiber for Road Concrete

In terms of road construction, problems such as cracks, shrinkage and poor durability may arise due to factors like heavy traffic, temperature variations and adverse weather conditions. Our high-strength polypropylene monofilament fibers are specifically designed to address these key issues, providing a reliable reinforcement solution for various-sized road concrete projects.Polypropylene monofilament fibers not only possess high strength and crack resistance, but also have excellent dispersibility. They can ensure uniform distribution without agglomeration, thus saving time when mixed with concrete and ensuring that every part of the road can be reinforced.

6mm PP monofilament fiber 12mm PP micro fiber

Concrete monofilament fiber specifications:

Raw Material | polypropylene |

Density(g/cm³) | 0.91~0.93 |

Color | Natural(White) |

Length(mm) | 4、6、10、12、15、19mm |

Tensile Strength(MPa ) | >370 |

Elastic Modulus(MPa ) | ≥3000 |

Fiber Diamater | 25~45um |

Crack Elongation(%) | ≥15 |

Melting Piont | 160-170℃ |

NOTE:length size 3 6 10 12 15 19mm,as custormer’s requirements | |

Concrete fiber polypropylene micro fiber main features:

◆The raw materials have stable performance and the polypropylene monofilament fibers have strong corrosion resistance.

◆Flexibility and high strength:The polypropylene fiber mortar fibers have good flexibility and can form a three-dimensional random network structure within the concrete or mortar. At the same time, they themselves have high strength, which can effectively disperse stress when the concrete is subjected to external forces, enhancing the toughness of the concrete.

◆Polypropylene fibers have excellent resistance to ultraviolet rays and oxidation. Even when exposed to outdoor environments for long periods, they are not prone to aging or degradation, and can continuously provide reinforcing protection for the concrete, extending the service life of the concrete structure.

◆Has good high dispersion

PP microfiber reinforced fiber function:

◆Adding reinforced polypropylene microfibers to concrete can suppress early cracks.

◆The use of concrete reinforcing fibers can reduce bleeding and segregation during concrete pouring, and improve surface flatness.

◆Polypropylene reinforced fiber concrete can also slow down the carbonation rate and chloride ion penetration rate, delay the corrosion of steel bars (if the structure contains steel bars), and extend the maintenance cycle.

◆The application of polypropylene fibers expands the application scenarios of concrete, enabling ordinary concrete to be used in areas with higher requirements for toughness and crack resistance, such as precast wall panels (reducing cracking due to insufficient thickness), shotcrete, and repair projects, where it can enhance the bond strength at the interface between new and old concrete and prevent cracking and peeling during repairs.

Applying instruction of pp micro fiber concrete fiber :

◆Length of polypropylene pp monofilament fiber:

Fine aggregate concrete such as mortar is suitable for polypropylene micro fiber length less than 12mm, and coarse aggregate concrete is suitable for concrete above 12mm.

◆Compounding Amount:for resisting the common cracks on surface,0.9kg/m ³fibers to cement mortar are enough.

◆Ratio and mixing requirements:the proportion of cement,sand and aggregate is no need to be changed.Put cement,aggregate,additive and fiber together,then stir after adding enough water and time for stirring can be prolonged for 2-3 minutes in order to make the compound mix completely.Also it can be mixed even with cement and other aggregates in advance,stirring by adding water at worksite before constructing.

Practical cases of polypropylene PP micro fiber:

◆A certain expressway pavement was doped with 0.9 kg/m³ PP monofilament fibers, reducing the crack incidence rate by 60% and extending the service life by 8 to 10 years

◆The industrial floor uses PP fiber concrete, which enhances its resistance to sulfate erosion by three times and extends the maintenance cycle from two years to six years

Road concrete monofilament fiber Industrial floor concrete pp micro fiber

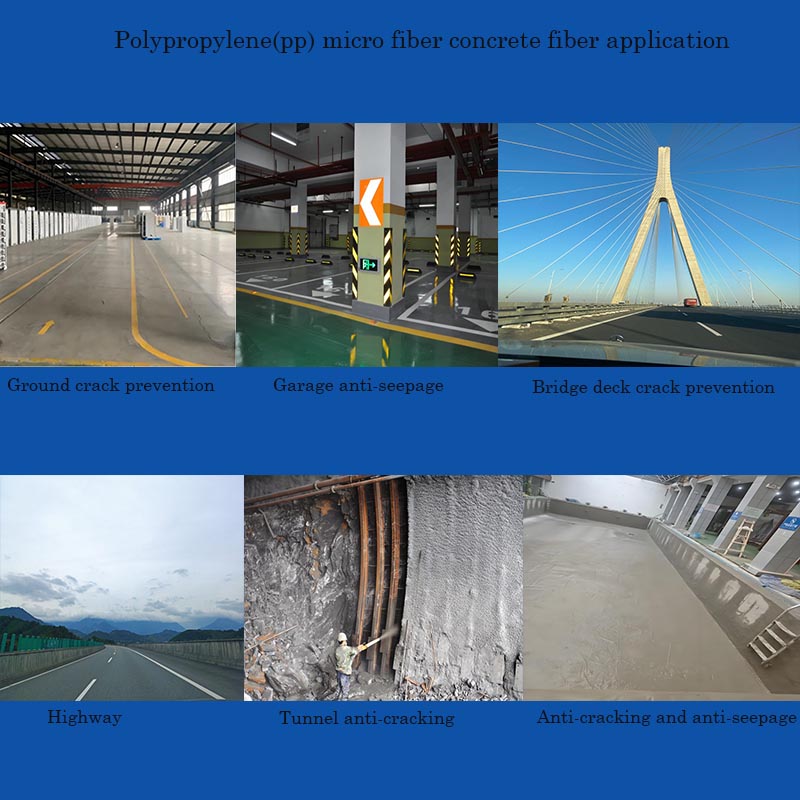

PP Microfibers applications:

◆polypropylene micro fiber is suitable for the water-proof layer, floor, inner & outer wall of industrial and civil construction.

◆Polypropylene fiber is used for surface cracking resistance and enhancement treatment of industrial workshop, warehouse and parking lot.

◆Increase cracking & seepage resistance of the ground in natatorium, swimming pool, pond and ditch.

◆Polypropylene micro pp fiber is suitable for any mortar projects and fine aggregate concrete projects.

◆Prefabricated components and prefabricated buildings.

Our polypropylene monofilament fiber for concrete is designed to enhance crack resistance and durability, widely used in road, bridge and tunnel concrete projects.

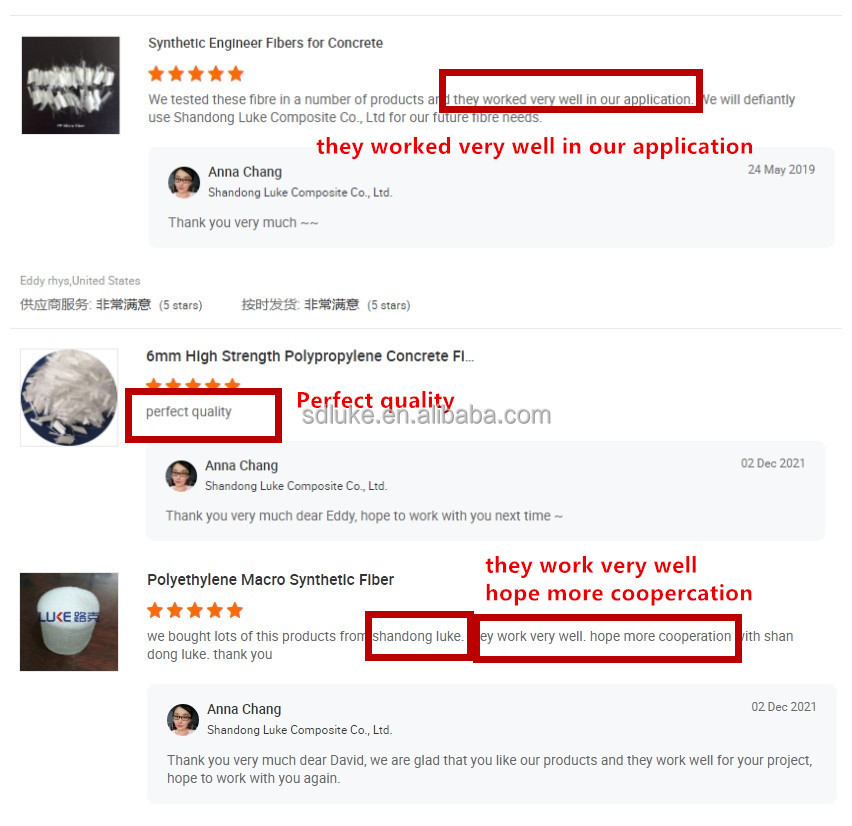

Customer evaluation:

About us:

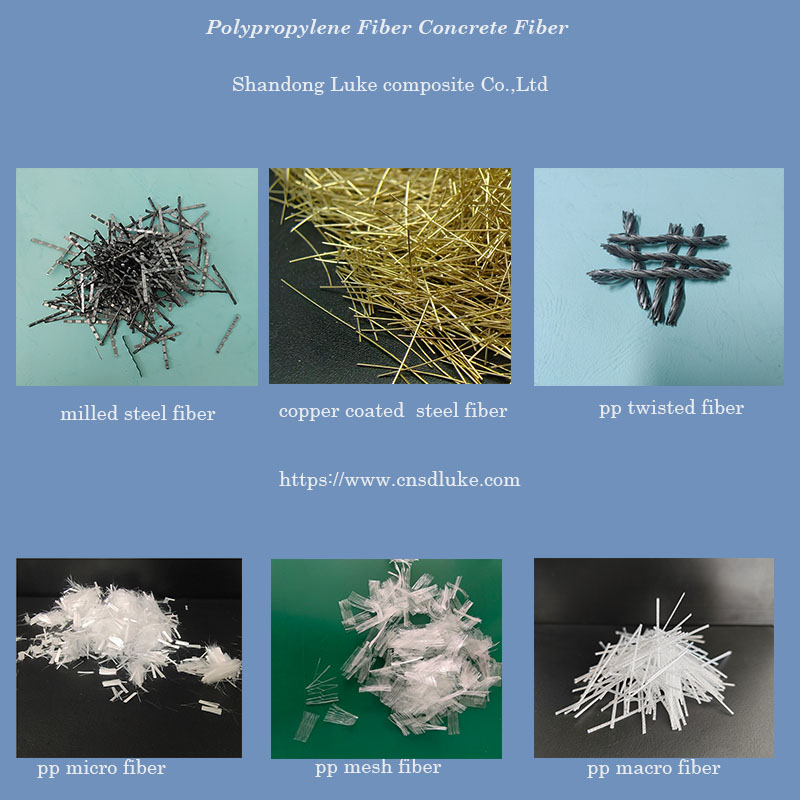

Shandong Luke composite Co., Ltd is a professional company on production and sales engineering anti-crack fiber.Concrete anti-crack fiber series such as polypropylene fiber、pp monofilament fiber(polypropylene micro fiber) 、polypropylene mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber etc.

Professional equipment, high quality polypropylene fibers series products, is your best choice, welcome to our company!

If you want to know more about the more concrete fiber polypropylene micro fibers ,you can continue to ask me questions.

Our company aim is: Quality first! Reputation first!

After-sales service:

Our company offers a one-stop service, providing 24/7 online support to solve any technical problems related to polypropylene micro fiber in a timely manner. Thank you for your love of our products.

Related Products

Submitted successfully

We will contact you as soon as possible