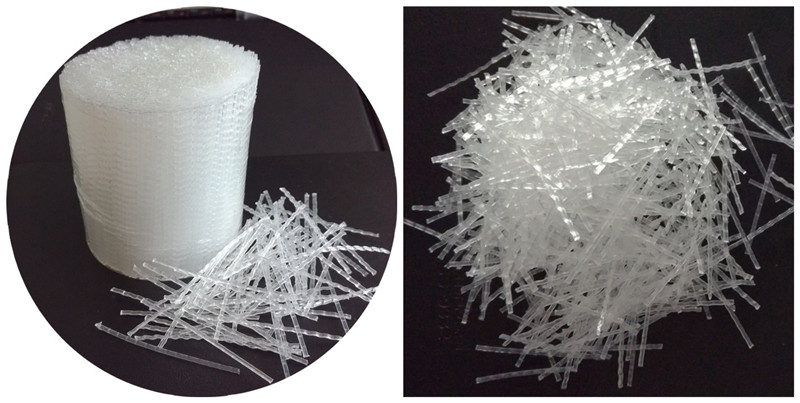

Macro Fiber of Polypropylene

100 % Pure Polypropylene

Good Dispersion

High Tensile Strength

Best for Concrete Reinforcement

One-stop Service,Strict Quality Control

Macro Fiber of Polypropylene

When macro fibers of polypropylene are added to the sprayed concrete, first mechanically mix the fibers with the dry materials (such as cement, sand and gravel) for 3 to 5 minutes to ensure uniform dispersion. Then add water for spraying. Alternatively, the fibers can be directly added to the wet mix, and the mixing time is extended to 2 to 3 minutes to avoid clumping. During the mixing process, due to friction and compression, the structure of the individual fibers will be damaged. Thus, by using a large number of polypropylene fibers, the concrete can be reinforced.

Parameter

Density(g/cm³) | 0.91 | Tensile Strength(Mpa) | ≥ 450Mpa |

Length(mm) | 6,12,18,24,36mm...... | Elastic Modulus(Mpa) | >3500 |

Shape | Beam-like Net | Equivalent Dia(μm) | 100±50 |

Material | 100% polypropylene | Crack Elongation(%) | ≥16 |

Water-Absorbency | No | Melting Point | 160-170 ℃ |

Feature

As a new type concrete-strengthening fiber, it becomes a new popular subject in the field of fiber concrete research and application.

The reinforced functions run as follows:

◆Increase seepage resistance

◆Prolong endurance

◆Improve steel protection

◆Increase cracking resistance

◆Increase fire resistance

◆Strengthen spurt & fatigue

◆Improve tensile, bending & folding strength

◆Improve plastic deformity

◆Strong acid & alkali resistance and good endurance

Application

- Projects like concrete road, bridge, airport road and factory floor which strictly require cracking resistance.

- The wall of tunnels, mines, roofs and reservoir projects with special construction.

- River courses and dams, etc.

- Military defense works, dock banks and piers, etc.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible