What Is The Best Polypropylene Fiber To Add To Concrete?

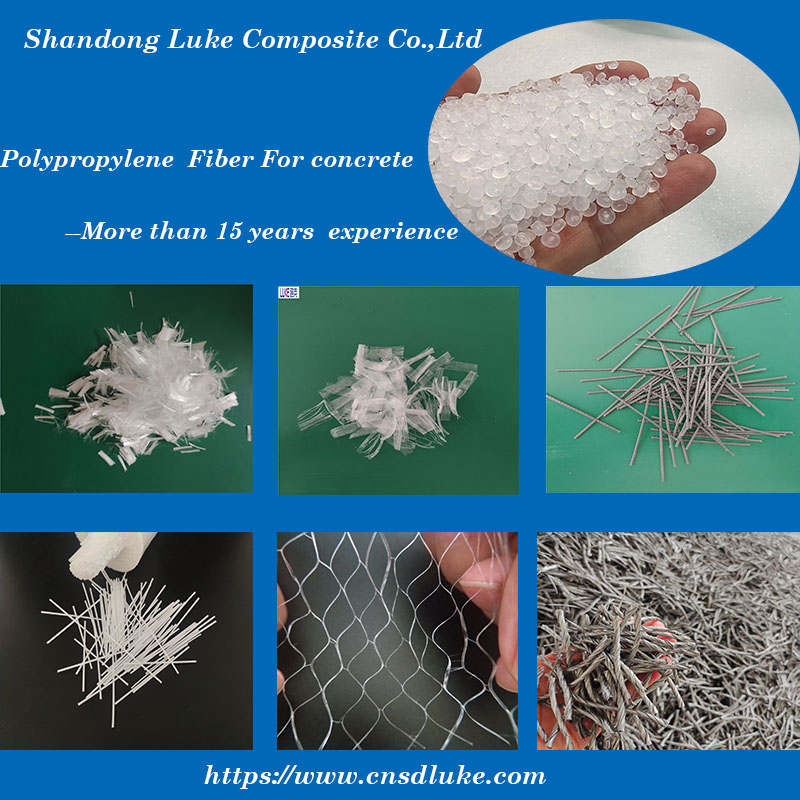

There are many types of polypropylene fibers, such as polypropylene macro fibers, steel-like fibers, polypropylene monofilament fibers, polypropylene twisted fibers, Polypropylene(PP) mesh fibers, etc. So, which type of fiber is the best to add to concrete? It needs to be judged comprehensively based on various factors such as the application scenario of the concrete, performance requirements (such as crack resistance, water permeability, enhanced toughness, etc.), construction conditions and cost. Here is an analysis of the characteristics and application scenarios of each type of polypropylene fiber, as well as our selection suggestions. You can choose based on your actual needs.

Type of demand | Recommended fiber | Advantages |

Anti-early plastic shrinkage | Good dispersion、Prevent initiation of microcracks | |

Resistance to cracking &Shock resistance | High strength、High tenacity、Prevent crack propagation and resist external force impacts | |

Mass concrete | Polypropylene macro fiber | Prevent temperature cracks and enhance the integrity of the structure |

Impervious、explosion-proof | Polypropylene mesh fiber、Polypropylene macro fiber

| Form a network structure to enhance the impermeability; release pressure at high temperatures to reduce the risk of cracking |

Low-cost anti-cracking | Polypropylene micro fiber, Polypropylene twisted fiber | Lower price, suitable for the general requirements of anti-cracking in engineering projects |

Damp &Corrosive Environment | Polypropylene macro fiber, Polypropylene fiber | Prevent metal corrosion and have better durability |