Effect of The Addition of Polypropylene Fiber on Concrete Properties

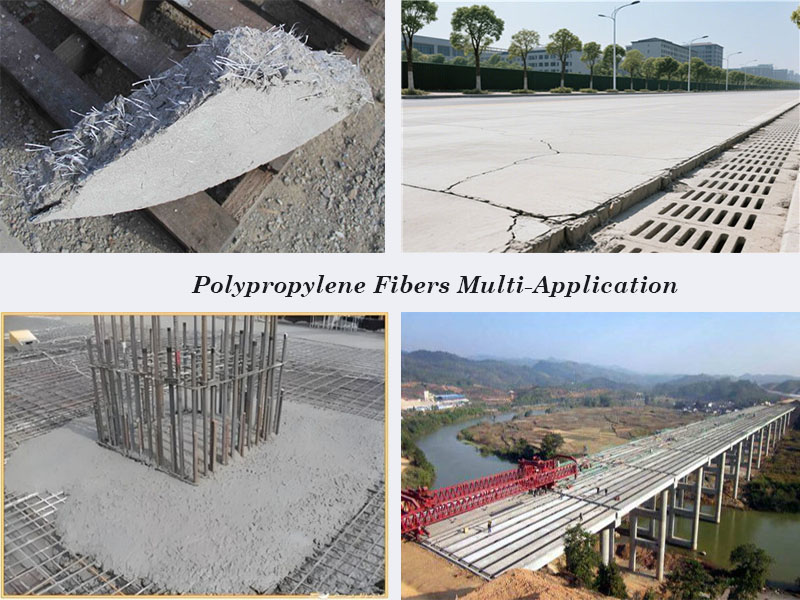

Polypropylene fiber(PP fiber) is a commonly used modified material for concrete. By physically adding it and evenly dispersing it in the concrete, its performance can be enhanced in multiple aspects, such as mechanical properties, durability, and workability.

1、Early cracking of concrete (such as plastic shrinkage cracks and drying shrinkage cracks) is a common defect. Polypropylene fibers can prevent plastic shrinkage and inhibit drying shrinkage. When hardened concrete undergoes shrinkage due to water evaporation or temperature changes, polypropylene fibers can transfer stress through interfacial bonding, reduce tensile stress caused by shrinkage, and thereby reduce the occurrence and development of cracks.

2、Improve compressive strength and impact resistance. Polypropylene fibers can enhance the ductility and toughness of concrete through the "crack bridging" effect.

3、Improve resistance to carbonation and chemical erosion.

◆In concrete containing polypropylene fibers, the depth of carbonation can be reduced by 25% to 40%;

◆In environments such as acid rain and salt alkali, after the fibers inhibit cracks, the erosion of sulfate and chloride ions on the cement stone can be reduced, thereby extending the service life of concrete.

4、Adding polypropylene macro fibers will not affect the fluidity and adhesion of concrete, and can enhance construction stability.