The Application Of Polypropylene Fibers In Concrete

In the concrete project of the basement floor slab of a large commercial complex, polypropylene macro fiber concrete was adopted in order to effectively control concrete cracks and improve the crack resistance and durability of the concrete.

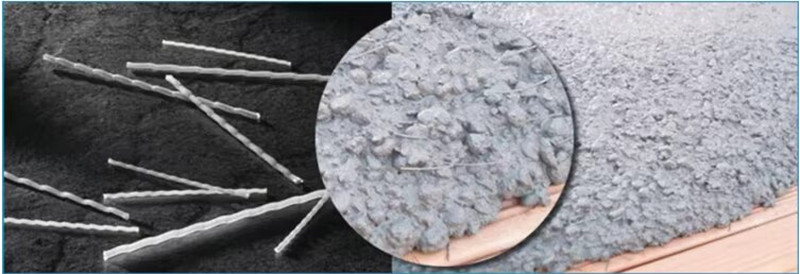

The basement floor has a large area. The design strength grade of the concrete is C35 and the impermeability grade is P8. In the design of concrete mix proportion, after many experiments and optimizations, it was finally determined that 0.9kg of polypropylene macro fibers would be added to each cubic meter of concrete. The length of the polypropylene macro fiber used is 50mm, the diameter is 0.8mm, its tensile strength is greater than 600MPa, and the elastic modulus is above 10GPa.

The application effect of polypropylene fibers:

The crack resistance performance has been significantly improved: In the early stage after concrete pouring, through on-site observation and crack monitoring, it was found that after the addition of polypropylene crude fibers, the plastic shrinkage cracks on the concrete surface were significantly reduced. Compared with ordinary concrete without fibers, the number of cracks has decreased by approximately 70%, and the width of the cracks has also significantly reduced. Enhanced toughness: During subsequent use, the basement floor concrete demonstrated excellent toughness. When subjected to certain impact loads, concrete does not exhibit brittle failure but shows better deformation capacity and energy absorption capacity. The support system formed by polypropylene crude fibers inside concrete can absorb and disperse energy when the concrete is impacted, preventing the concrete from being damaged due to local stress concentration and effectively enhancing the toughness of the concrete.

Improved impermeability: According to the results of the impermeability test, the impermeability of concrete with polypropylene crude fibers added has been significantly improved. This is because the addition of polypropylene crude fibers makes the internal structure of the concrete more compact. The fibers fill some tiny voids, reducing the formation of interconnected capillary pores, thereby lowering the permeability of the concrete and enhancing its impermeability.

Durability improvement: After long-term usage observation and regular inspection, the concrete of this basement floor has performed outstandingly in resisting environmental erosion, temperature changes and other factors, and its durability has been significantly enhanced. The acid and alkali corrosion resistance of polypropylene crude fibers and their reinforcing effect on concrete structures effectively extend the service life of concrete structures.