Fiberglass Mesh for Wall Reinforcement

Fiberglass mesh cloth has High cost-effectiveness, with costs much lower than those of metals and carbon fiber reinforced materials can meet most of the building reinforcement requirements.

Construction is convenient: lightweight and flexible, it can be freely cut, and can be quickly laid to shorten the construction period.

Capable of withstanding extreme temperature variations, it does not age, deform or deteriorate easily in humid, exposed to direct sunlight, acidic or alkaline environments, and has a long service life.

Excellent compatibility, good adhesion to the building substrate, and no problems such as delamination or detachment will occur.

High Tensile Strength Construction Fiberglass Mesh Cloth

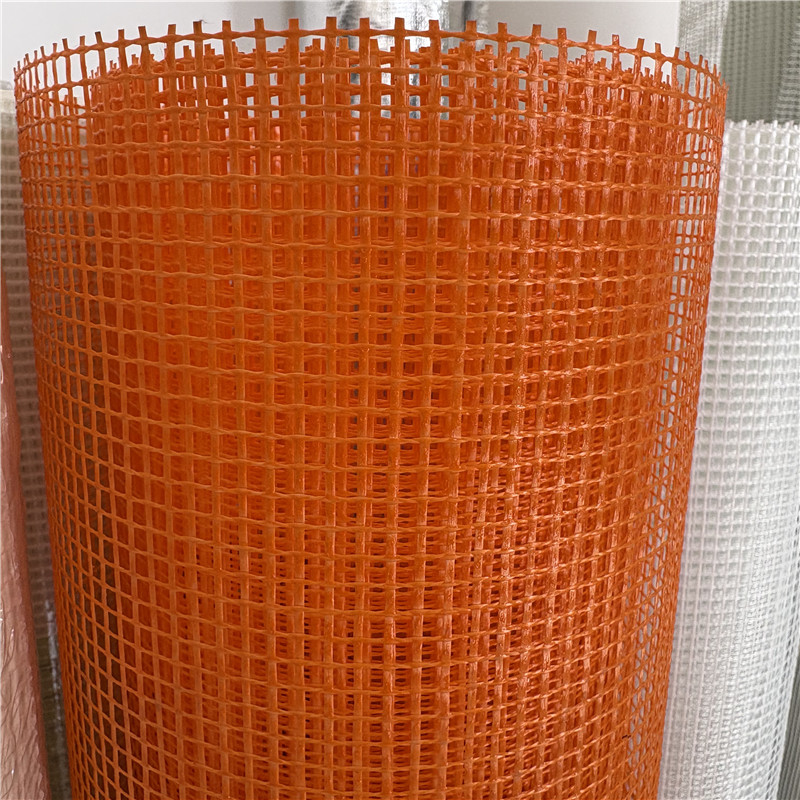

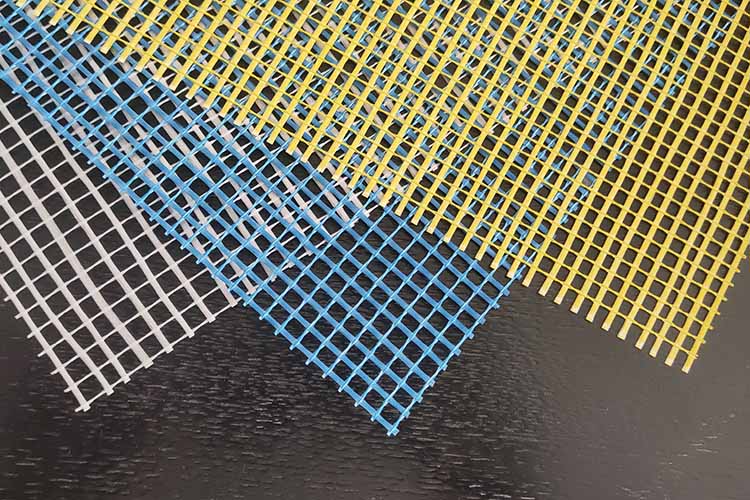

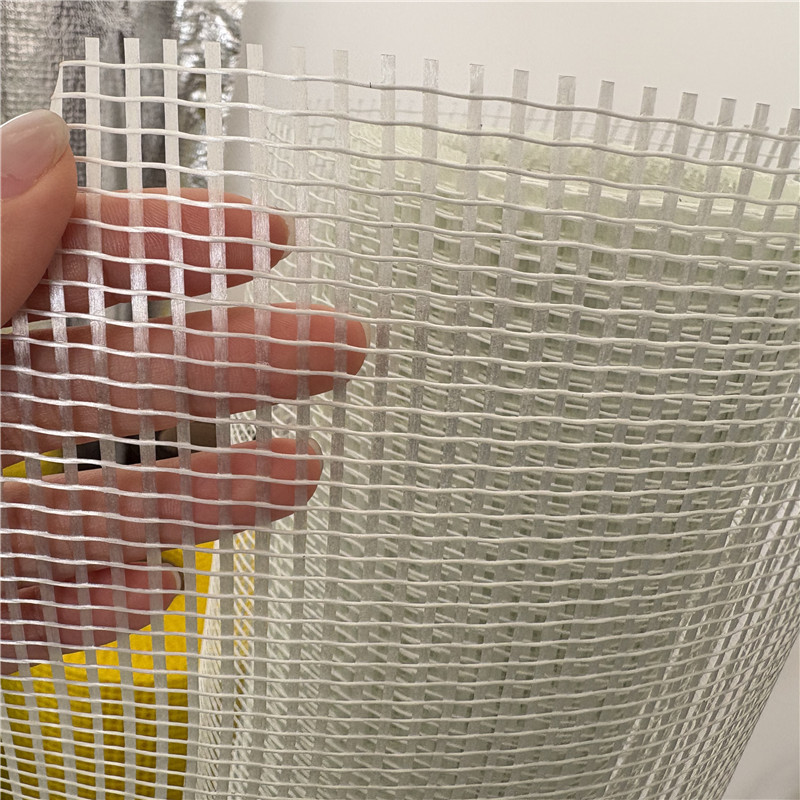

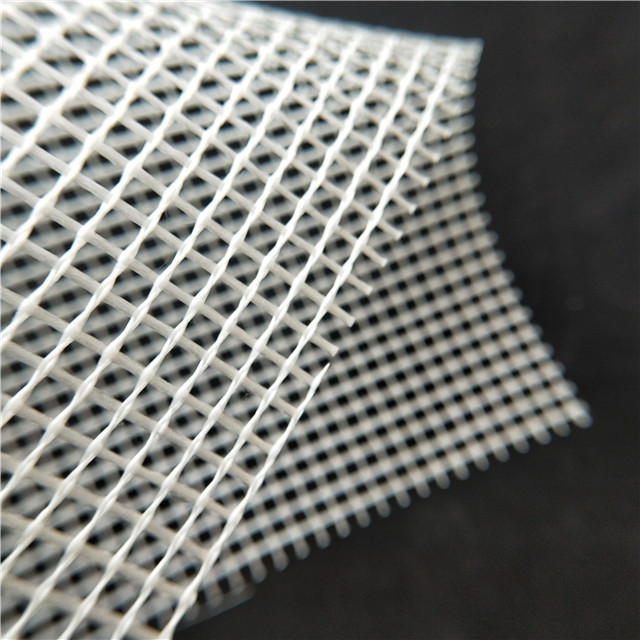

Glass fiber mesh cloth is a type of building reinforcement and protective material made from E-type glass fibers as the base material. It is woven into a mesh structure and then treated with an alkali-resistant coating.Its core structure consists of interwoven weft and warp threads, with uniform pore sizes (commonly 4×4mm, 5×5mm), and the weight range is between 80g/㎡ and 200g/㎡. It is lightweight yet extremely strong in toughness, and is a fundamental material used in the construction field for preventing cracking and reinforcement.

Alkali-resistant fiberglass mesh product specification:

Specification Item | Options |

material | E-Glass Fiber |

Weight | 80g/㎡,120g/㎡,160g/㎡,200g/㎡ or customized according to your need |

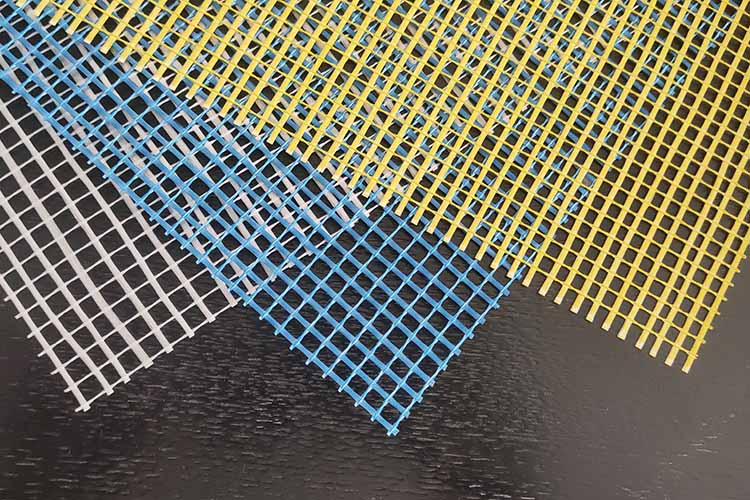

Mesh size | 4*4mm,5*5mm,6*6mm,8*8mm |

Width | 1m~2m |

Length per roll | 50m—200m |

Tensile strength | excellent |

Color | White, blue, yellow, green, orange, etc |

MOQ | 50 Rolls |

Application | Wall materials, External wall insulation |

Construction fiberglass mesh feature:

◆Excellent alkali resistance

The surface has been treated with an alkali-resistant coating, which enables it to maintain over 90% of the tensile strength even in alkaline environments such as cement and gypsum, preventing the fibers from being corroded and failing.

◆High tensile strength

It is woven with E-type glass fibers, featuring high tensile strength, which can effectively disperse the wall stress and prevent the occurrence and expansion of cracks.

◆Uniform grid structure

Standard grid hole diameters of 4×4mm and 5×5mm ensure uniform force distribution, allowing the bonding material to fully penetrate and form a solid "protective layer".

◆Lightweight design

The weight is only 80 to 200 grams per square meter. After installation, it will not add extra weight to the wall, making it suitable for scenarios where load-bearing capacity is sensitive, such as high-rise buildings and lightweight partitions.

Glass fiber mesh main function:

◆Anti-crack reinforcement

Anti-crack fiberglass mesh can disperses stresses caused by temperature changes, foundation settlement, etc., preventing cracks and hollowing on the wall surface.

◆Enhanced adhesion

increases the contact area of the materials and enhances the bonding strength, preventing the decorative surface from falling off.

◆Anti-seepage and moisture-proofing

After the grid structure is combined with the bonding material, a dense protective layer can be formed, reducing water penetration and lowering the risks of mold growth and alkali return on the wall.

◆Structural reinforcement

Used in the production of prefabricated components such as cement boards, gypsum boards, and flue ducts, it improves the bending and impact resistance of the products and extends their service life.

Fiberglass mesh cloth application:

◆External wall external insulation system (EIFS)

It is placed between the insulation board and the anti-crack mortar to prevent the insulation layer from cracking due to thermal expansion and contraction.

◆Interior and exterior wall plastering project

It is laid at the connection between new and old walls, and at the junction of concrete beams and columns and brick walls to solve the problem of cracks caused by different material shrinkage rates.

◆Tile / stone laying

When laying large-sized tiles, exterior wall cultural stones, and marble, a mesh is placed on the back for reinforcement, which is especially suitable for damp bathrooms, kitchens, and exterior walls.

◆Ceiling and lightweight partition walls

It is laid at the joint of gypsum board ceilings and the surface of lightweight steel frame partition walls to enhance the stability of the ceiling and avoid partition wall cracking.

◆Pre-fabricated building materials production

It is used to manufacture fiberglass cement boards, gypsum lines, and insulation and decoration integrated panels, etc., to enhance the strength and toughness of prefabricated components.

Packing&Delivery

It is roll on a paper core with a diameter of 55 mm or 75 mm, then packed into a polyethylene bag, then outside packed into a cardboard box. Finally, the product can be either shipped with cardboard box only or with pallet.

About us:

Shandong Luke Composite Co., Ltd is a professional company which has more than ten years working in the field of Geo- materials,also has a professional team for export business.Our geo-synthetic materials have been exported to more than 30 nations and regions, such as Southeast Asia,Australia, North America, Europe, Middle East and Africa.Our geotechnical materials include:

◆ Fiberglass Mesh Cloth

◆ Geotextile

◆ Geogrid

◆ 3D Geomat

◆ Geocell

◆ Drainage board

Welcome to choice the products you need!supply qualified products, competitive price and efficient service, achieve the goal of long term cooperation.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible