HDPE Geo Textile Drainage Board For Roadbed

It is a professional drainage board for roadbeds

The material structure is stable, with strong anti-aging performance

The hdpe geo textile drainage board has excellent corrosion resistance

The drainage efficiency is high and the service life is long

It does not deform under low or high temperatures

Its tensile strength and tear strength have reached a relatively high level, and it is unlikely to be damaged during construction processes such as roadbed compaction

HDPE Geo Textile Drainage Board For Roadbed

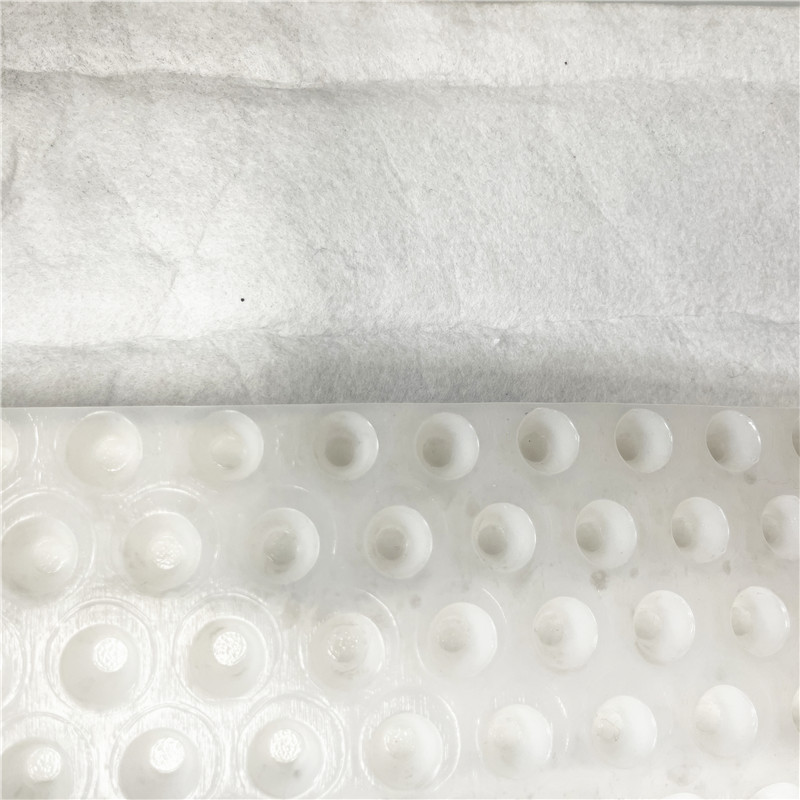

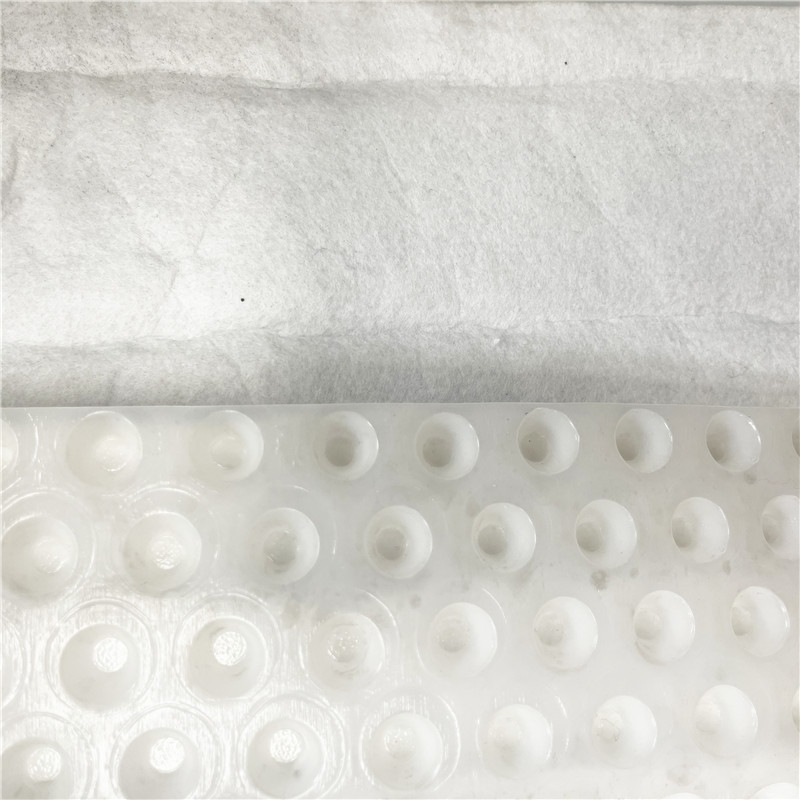

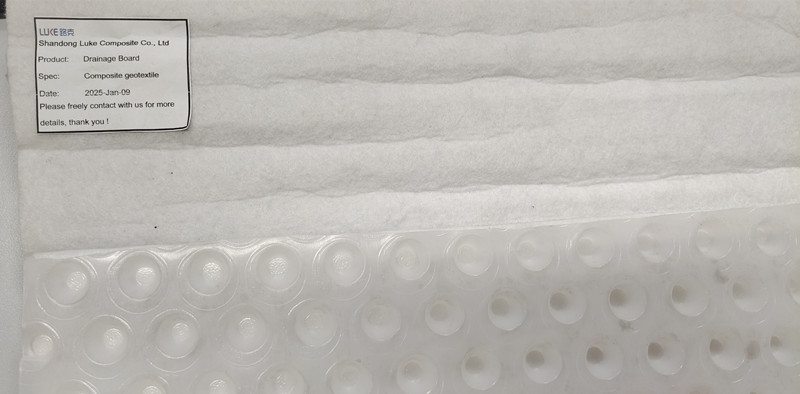

The HDPE geo textile drainage board, as a high-performance drainage dimple board for roadbeds, is mainly made of high-density polyethylene and is processed through advanced extrusion molding technology. It combines the composite characteristics of the geotechnical drainage board with the structural advantages of the high-strength drainage board, occupying an important position in the field of geo textile drainage boards for underground engineering. Its unique convex point structure design enables the product to have excellent drainage function while also being able to withstand large loads, making it highly suitable for the usage requirements of roadbed environments. This structure not only increases the space of the drainage channels but also enhances the overall compressive strength of the board, effectively coping with various pressures during roadbed construction and use.

HDPE geo textile drainage board for roadbed technical parameter:

Parameter item | Range | Notes |

Material | HDPE | |

Thickness | 20-50mm | Can be customized according to engineering requirements |

Length | 10m/roll | According to your requirements |

Width | 2m | Reduce seams and enhance work efficiency |

Height of the protrusion point | 20-50mm | The higher the height, the larger the drainage space |

Temperature tolerance range | -40℃~80℃ | Stable Performance |

Function | Water drainage | |

Geo textile drainage board for roadbed feature:

◆The drainage efficiency is high. The gaps between the protrusions form an efficient drainage network, which can quickly drain the accumulated water from the roadbed.

◆In the application of composite drainage boards in underground engineering, it also has the advantage of convenient construction. It is lightweight, easy to lay, and can significantly shorten the construction period and reduce the project cost.

◆The protrusions and thickness can be adjusted according to different projects. The production is flexible and the practicality is high.

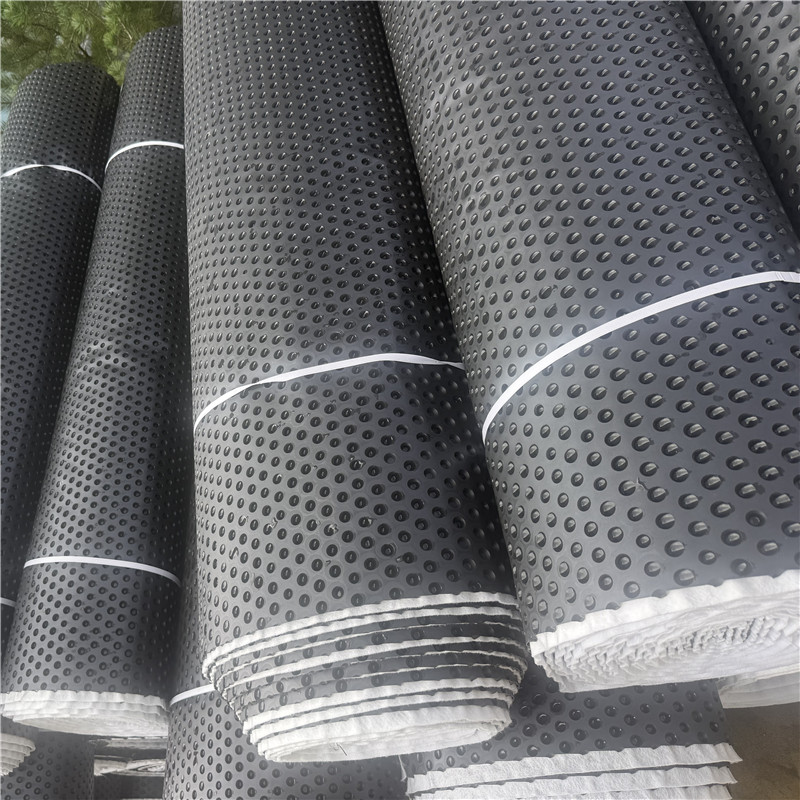

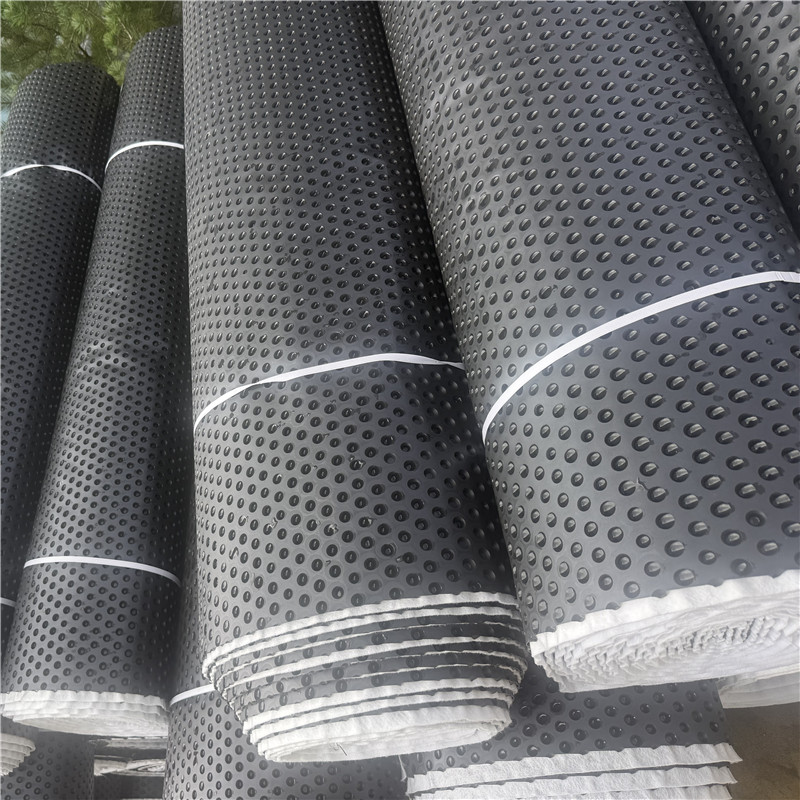

Composite geo textile drainage board packaging and transportation:

The composite geo textile drainage boards are packaged in double-layer waterproof woven bags, with each roll independently sealed and equipped with an inner moisture-proof film to ensure it is not affected by rain during transportation. Customized pallet packaging service is provided, with each pallet capable of stacking 6 to 8 rolls, saving transportation space and reducing logistics costs.

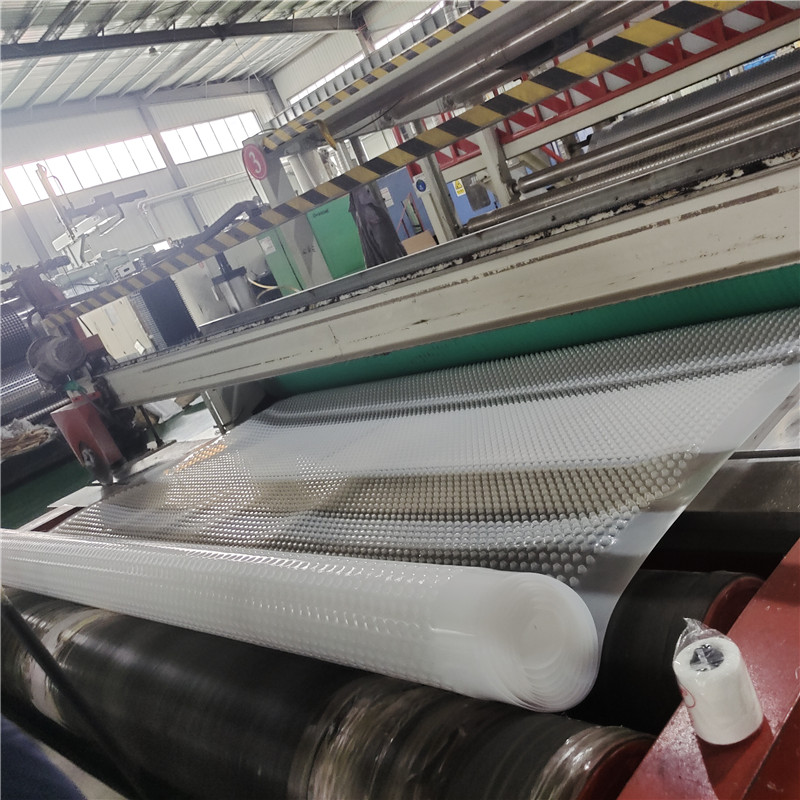

Our company introduce advanced production lines to achieve full-process automation control from raw material mixing, extrusion molding to composite pressing. The production accuracy can reach ±0.1mm. The raw materials are selected from high-quality HDPE particles. Each batch of raw materials undergoes multiple indicators tests to ensure stable quality.

The function of the subgrade drainage dimple board in the roadbed:

HDPE composite geotextile drainage boards play a crucial role in roadbed engineering. As a key drainage board for roadbeds, it can promptly drain the accumulated water inside the roadbed, prevent water from accumulating in the roadbed, and avoid diseases such as frost heave and settlement of the roadbed. The characteristics of high-strength drainage boards ensure that the drainage channels will not be compressed and blocked under the action of vehicle loads and their own weight, maintaining unobstructed drainage. The structure of the composite geotechnical drainage board also enables it to have a certain isolation effect, separating the roadbed soil from other materials, preventing the mixture of different materials, and ensuring the stability of the roadbed structure. In the application system of composite drainage boards in underground engineering, it effectively lowers the groundwater level, reduces the impact of water pressure on the roadbed, and provides a strong guarantee for the long-term stability of the roadbed.

After-sales service:

Our company provides a one-stop service, and our technical staff provides 24/7 online support to solve any technical problems related to hdpe composite geotextile drainage boards in a timely manner. Thank you for your love of our products.

Our commitment:

Professional equipment, high quality drainage boards series products, first-class service is your best choice, welcome to our company!

HDPE composite drainage boards application :

HDPE composite drainage boards have a wide range of applications. Besides being mainly used as drainage boards for road subgrades in road and railway subgrade drainage projects, they also have important applications in other fields. As a high-strength drainage board, it can be used for the base layer drainage of airport runways to ensure that the runways do not affect safety due to water accumulation. The characteristics of the composite geotechnical drainage board make it suitable for the reinforcement drainage of road subgrades in municipal roads, extending the lifespan of the roads. In underground engineering, as an underground composite drainage board, it can be applied to the drainage systems of underground garages, tunnels, and other projects, effectively solving drainage problems in the projects and providing reliable drainage guarantees for the safety and stability of various projects.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible