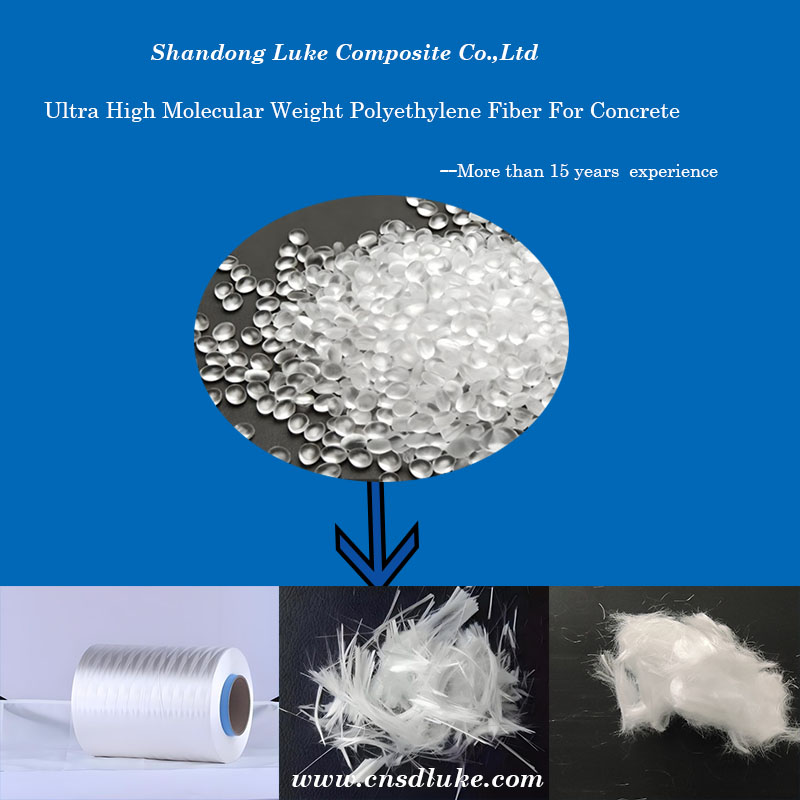

Ultra High Molecular Weight Polyethylene Fiber For Concrete

High specific strength, high specific modulus.

The specific strength is more than ten times that of steel wire of the same cross-section, and the specific modulus is second only to extra grade carbon fiber

UHMWPE fiber is the ideal toughening material for UHPC

It has excellent physical properties.

The fiber is lightweight and high strength suitable for special structures and works.

Ultra High Molecular Weight Polyethylene Fiber For Concrete

Ultra-high molecular weight polyethylene fiber (UHMWPEF), also known as high strength and high modulus polyethylene fiber, is one of the highest specific strength and specific modulus fibers in the world today. The fibers typically have a molecular weight of between 1 million and 5 million and are spun from ultra-high molecular weight polyethylene (UHMWPE). The preparation process of UHMWPE fiber is relatively complicated. During the production process, the molecular structure of the raw material will change significantly, gradually changing from a disordered state to a partially ordered state, forming a fiber with high strength and high modulus. It not only has excellent physical properties, but also shows extensive application potential in many fields. Ultrahigh molecular weight polyethylene fibers are introduced into concrete to overcome and improve the performance and durability of concrete.

UHMWPEF fiber concrete fiber feature:

◆High strength and toughness: Ultra-high molecular weight polyethylene fiber has very high tensile strength and tensile modulus, and can absorb a lot of energy during the stretching process. This allows the concrete to withstand greater loads and strains, reducing crack formation and propagation.

◆Corrosion resistance: Ultra-high molecular weight polyethylene fiber has excellent corrosion resistance and can work stably in harsh environmental conditions for a long time. This is particularly important for Marine engineering, chemical plants and other places with harsh environments.

◆Uv resistance: Ultra high molecular weight polyethylene fiber has good UV resistance and can effectively protect concrete from UV damage.

UHMWPE fibers technical parameters:

Place of origin | Shandong,China | Product Name | UHMWPE Fiber |

Density | 0.97g/cm³ | Modulus | 91-140N/tex |

Tensile Strength | 2.8-4N/tex | Crack Elongation | 3.5-3.7% |

Diameter | 20-40um | specification | 6,12,15,18 or customized |

Acid and alkali | Strong | Abrasion performance | strong |

The specific application of ultra high molecular weight polyethylene fiber in concrete:

◆Directly added to concrete mix : Adding UHMWPE fiber directly to concrete mix can effectively disperse the fiber and form a three-dimensional network structure in the concrete, thus improving the crack resistance and toughness of concrete.

◆Laying fiber mesh : Laying UHMWPE fiber mesh on the surface of concrete can enhance the surface strength and durability of concrete and prevent surface cracking.

Application of ultra high molecular weight polyethylene fiber in concrete:

Enhance the strength and toughness of concrete: Ultra high molecular weight polyethylene fiber can increase the tensile strength and impact resistance of concrete, reduce the generation and expansion of cracks. This is very important for structures that need to withstand large loads and severe deformation, such as Bridges, high-rise buildings, etc.

Improve the durability of concrete: UHMWPE fiber can improve the durability of concrete and reduce the cracking and corrosion caused by environmental factors such as temperature, humidity and chemicals.

Application:

◆Explosion-proof building:

UHPC and UHMWPE fiber composite material is used for high-strength special shelter, impact resistance protection layer.

◆Bridges and buildings

• Earthquake-resistant structure: Fiber reinforced UHPC is used for bridge joints and key nodes of high-rise buildings to improve earthquake toughness.

• Lightweight prefabricated components: Replace some steel fibers with UHMWPE fibers, reducing transportation and installation costs.

◆Oceans and extreme environments

• Seawater corrosion environment: UHMWPE fiber does not rust, suitable for offshore platforms, undersea tunnel lining.

About us:

Shandong Luke composite Co.,Ltd is a professional company on production and sales engineering anti-crack fiber. Concrete anti-crack fiber series such as polypropylene(PP) fiber、polypropylene(PP) mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved polypropylene(pp) macro fiber、twisted bundle polypropylene fiber、steel fiber、basalt fiber and UHMWPEF(Ultra High Molecular Weight Polyethylene Fiber) fiber.

Professional equipment, high quality polypropylene fiber concrete fibers , is your best choice, Welcome to request product prices!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible