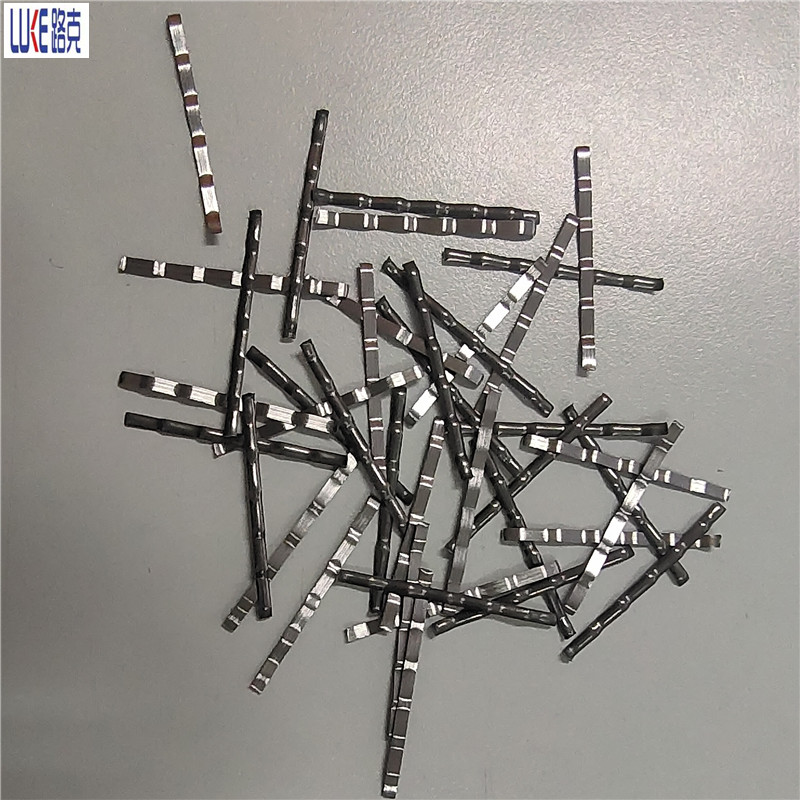

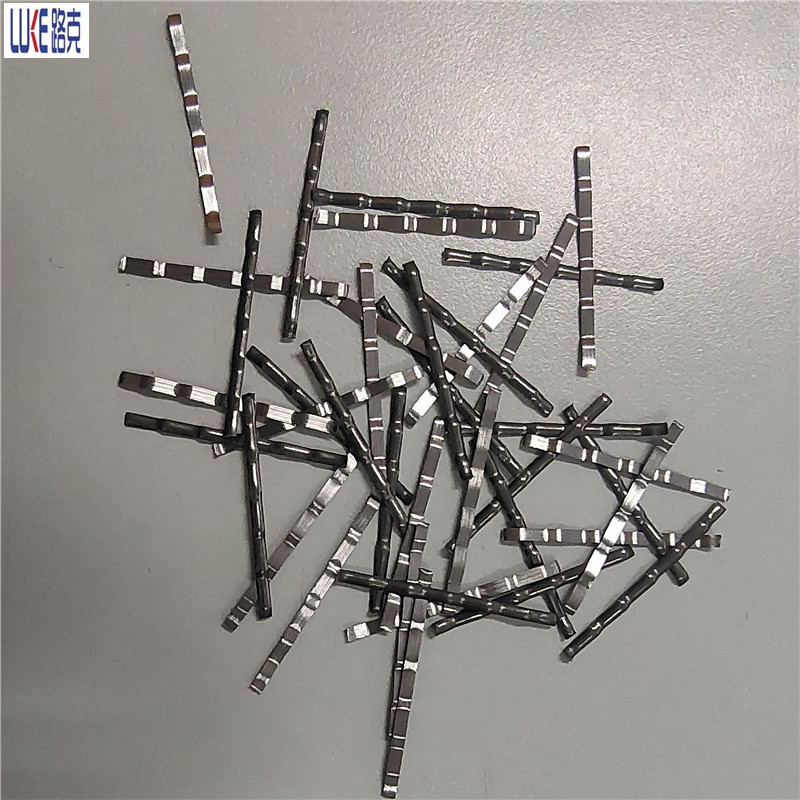

Steel Fiber for Reinforcement Strengthen Cement Road Structure

Steel fiber has high strength

Steel fiber reinforced concrete has good durability

Strong crack resistance

Steel fiber specifications, models to meet different customer requirements

Stable quality, ensure the quality of products out of the standards.

We can provide steel fiber samples free of charge.

Steel Fiber for Reinforcement Strengthen Cement Road Structure

There are many specifications for steel fibers. The commonly used length range is 10 to 60 millimeters, the diameter is 0.2 to 1.2 millimeters, and the aspect ratio is 30 to 100. Specifically, steel fibers with a length of 20 to 50 millimeters, a diameter of 0.3 to 0.8 millimeters, and an aspect ratio of 40 to 100 have excellent reinforcing effect and mixture performance.

The reinforcing effect of steel fibers is closely related to length, diameter and aspect ratio. Too short length has no reinforcing effect, while too long length affects the quality of the mixture; too thin diameter is prone to being bent during the mixing process, and too thick diameter results in poor reinforcing effect. Therefore, choosing the appropriate length and diameter is crucial for the reinforcing effect of steel fibers.

Steel fiber for reinforcement strengthen cement road structure function:

Compared with ordinary concrete pavement, steel fiber reinforced concrete pavement can significantly reduce the thickness of concrete slabs, extend the spacing of contraction joints, reduce the number of joints, improve pavement performance, thereby reducing workload, shortening construction period, extending service life and ensuring driving comfort.Steel fiber reinforced concrete road is mainly applied to sections with restricted elevation, toll stations, concrete overlay and bridge deck pavement.

Steel fibers features:

◆ High intensity

Steel fibers are made of high-strength steel and can significantly improve the tensile, flexural and shear strength of concrete.

◆ High toughness

Steel fibers can absorb energy and improve the toughness of concrete, making it less vulnerable to brittle damage when subjected to impact or dynamic loads.

◆ Good bonding performance

Steel fiber surfaces are usually specially treated (such as indentation, bending hooks, etc.) to enhance their adhesion to the concrete matrix and ensure that the fiber can effectively transfer stress.

◆Distribute evenly

The steel fiber can be evenly distributed in the concrete, forming a three-dimensional network structure, thus comprehensively enhancing the performance of the concrete.

◆ Excellent crack resistance

Steel fiber can effectively restrain the plastic shrinkage cracks and dry shrinkage cracks of concrete, and limit the expansion of cracks.

◆Good durability

Steel fiber can improve the fatigue resistance, wear resistance and impact resistance of concrete, and prolong the service life of the structure.

◆Convenient construction, strong adaptation

The steel fiber can be directly added to the concrete mixing, simplifying the process and saving cost.

◆Economical and environmentally friendly, recyclable.

Product specifications and parameters of steel fiber:

Product Name | Steel Fiber | Place of origin | Shangdong,China |

Raw Material | High quality steel wire | Tensile strength(MPa) | ≥600 |

Shape | End hook or customizable | Equivalent diameter(mm) | 0.3-1.0 |

Length | ≥25 | L/D ratio | 30-80 |

packaging | 20kg per bag | Application | Concrete Reinforced |

The function of steel fibers in concrete:

The addition of steel fiber significantly enhances the durability of concrete, effectively prevents water seepage, oil seepage and gas seepage caused by cracking, and greatly improves the tensile strength of concrete. Second, steel fibers enhance the toughness of concrete, making it more resistant to breakage when impacted, maintaining the stability of the structure, and enhancing the cracking resistance. Therefore, concrete mixed with steel fiber is especially suitable for large-scale projects and special buildings.

Application scenarios of steel fibers

◆Industrial floors: Places that withstand heavy loads and wear.

◆Roads and Bridges: Improve crack resistance and durability.

◆Tunnels and mines: Enhanced impact and crack resistance.

◆Hydraulic engineering: Improve impermeability and durability.

◆Earthquake-resistant structure: improve the toughness and energy absorption capacity of the structure.

◆Special engineering: Enhanced knock and shock resistance.

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to steel fiber in a timely manner. Thank you for your love of our products.we can provide the steel fibers solution.

One-stop Service, Strict Quality Control.

About us:

Shandong Luke composite Co.,Ltd is a professional company on production and sales engineering anti-crack fiber. Concrete anti-crack fiber series such as polypropylene(PP) fiber、polypropylene(PP) mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber、basalt fiber etc. Our polypropylene fibers have been exported to more than 30 nations and regions, such as Southeast Asia, Australia, North America, Europe, Middle East and Africa.

Professional equipment, high quality polypropylene fibers series products, is your best choice, Welcome to request product prices!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible