Dimple Drainage Board Has Been Shipped

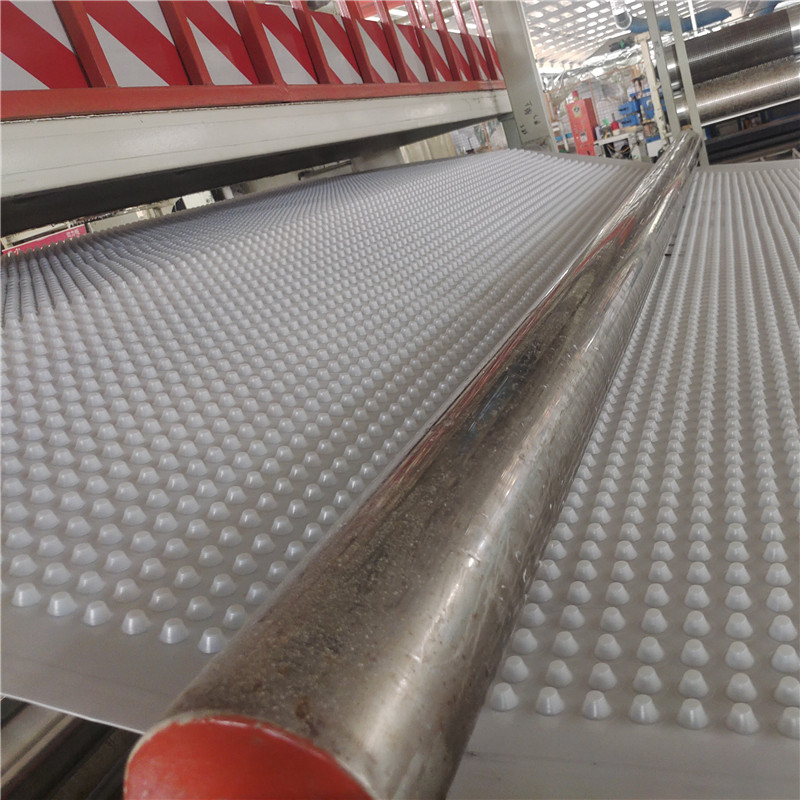

Today, the drainage boards ordered by the customer have completed the final quality inspection process and are officially being loaded onto the vehicles for shipment. This batch of drainage boards is made of HDPE material. With its unique molecular structure and advanced extrusion molding process, it features strong compressive strength and high drainage efficiency. It can quickly drain water accumulated in soil, rooftops or underground projects, effectively preventing leakage and water accumulation hazards, far exceeding industry standards. It can be used as subsurface drainage board, a roof drainage board, foundation drainage board.

To ensure the integrity of the drainage boards during transportation, we use a roll packaging method, and each roll of the product is tightly wrapped in white woven bags. These woven bags have the characteristics of moisture-proof, wear-resistant, and tear-resistant, ensuring that the products remain stable and not loose during transportation.

Quality is our lifeline. Before packaging each roll of drainage boards, they must undergo strict quality inspection processes. For example, the thickness of the drainage boards, the height of the protrusions, the tensile strength, and other core indicators are tested to ensure that all parameters meet the customer's customization requirements.

For the drainage boards being shipped this time, every aspect from raw material control to product delivery has been infused with our craftsmanship and dedication. We deeply understand the trust and expectations of our customers, and will ensure that this order meets and even exceeds customer expectations with high-quality products and services, safeguarding the smooth progress of the project.