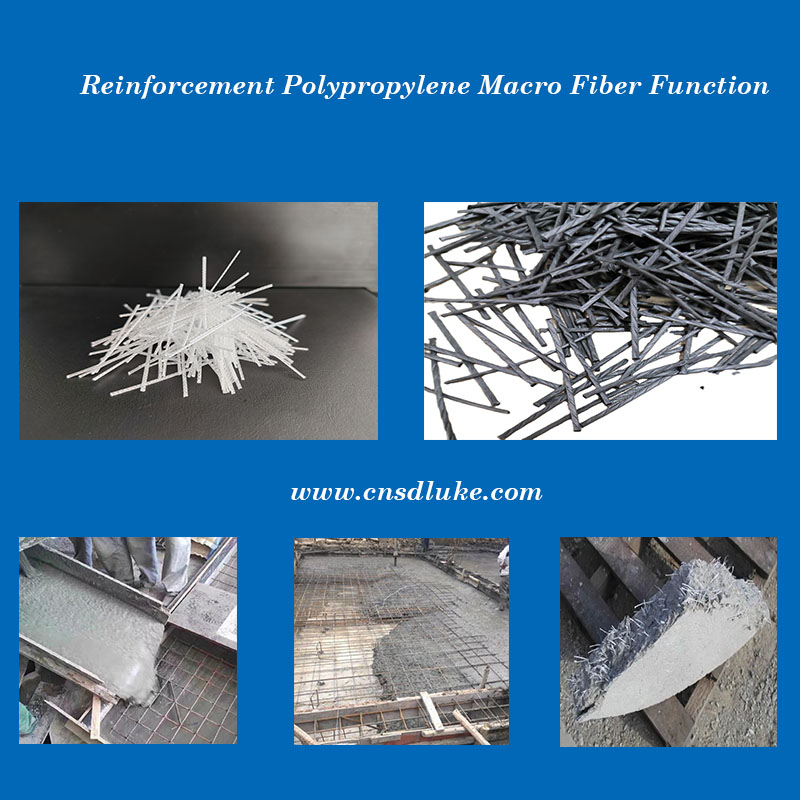

polypropylene Macro Concrete Fiber Has Been Shipped

In recent years, with the rapid development of global infrastructure construction, the demand for high-performance engineering materials continues to grow. As a global manufacturing power, China has made continuous breakthroughs in the field of high-strength concrete fiber materials. Today, the pp macro fiber produced by our company has been loaded and ready to go. It marks the further improvement of the competitiveness of China's high-end engineering materials in the international market.

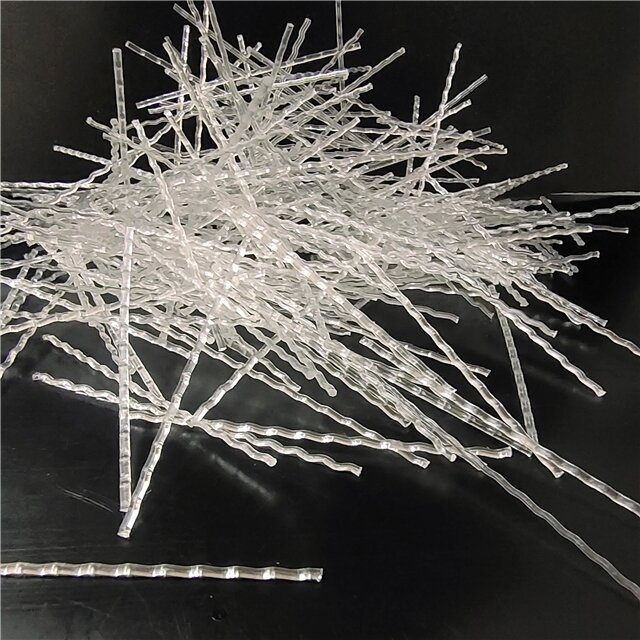

Macro fiber is a special fiber used to strengthen concrete, asphalt and other building materials, which can significantly improve the crack resistance, wear resistance and impact resistance of engineering structures. The polypropylene macro fiber exported to Europe has the following core advantages:

◆ Excellent crack resistance

• Inhibit plastic shrinkage cracks: In the initial hardening of concrete (24 to 72 hours), the concrete fibers form a three-dimensional network to reduce cracks caused by water evaporation.

• Reduce dry shrinkage cracks: In long-term use, the polypropylene fibers can disperse stress and reduce the risk of cracking.

◆ Improved impact resistance and toughness

• The high modulus (3~10GPa) of crude fiber can significantly improve the bending strength and toughness of concrete, which is suitable for high impact scenarios such as special engineering and airport runways.

• More fatigue resistant than steel fiber, not easy to break under repeated load.

◆ Durability and life extension

• Freeze-thaw resistance: The microporous structure inside the fiber can relieve frost heave pressure, suitable for cold areas.

• Resistance to chloride ion penetration: protect steel bars and extend the life of reinforced concrete structures.

◆ Construction convenience

• No additional equipment required: mixing directly into concrete, easier to operate than steel fiber.

• Safety and environmental protection: no risk of rust, no damage to the pumping equipment, safer construction for workers.

◆ Economy

• Low comprehensive cost: compared with steel fiber, the price is lower, and the cost of anti-rust treatment is saved.

• Reduce maintenance costs: Extend the service life of concrete structures and reduce repair frequency.

Welcome to your inquire!