End Hooked Steel Fiber For Reinforced Concrete

End hooked steel fiber is a high perfomance steel fiber.

Steel fiber reinforced concrete has good durability.

Concrete reinforced steel fibers have good strong crack resistance.

Steel fiber specifications, models to meet different customer requirements.

It has good tensile properties.

Stable quality, ensure the quality of products out of the standards.

We can provide steel fiber samples free of charge.

End Hooked Steel Fiber For Reinforced Concrete

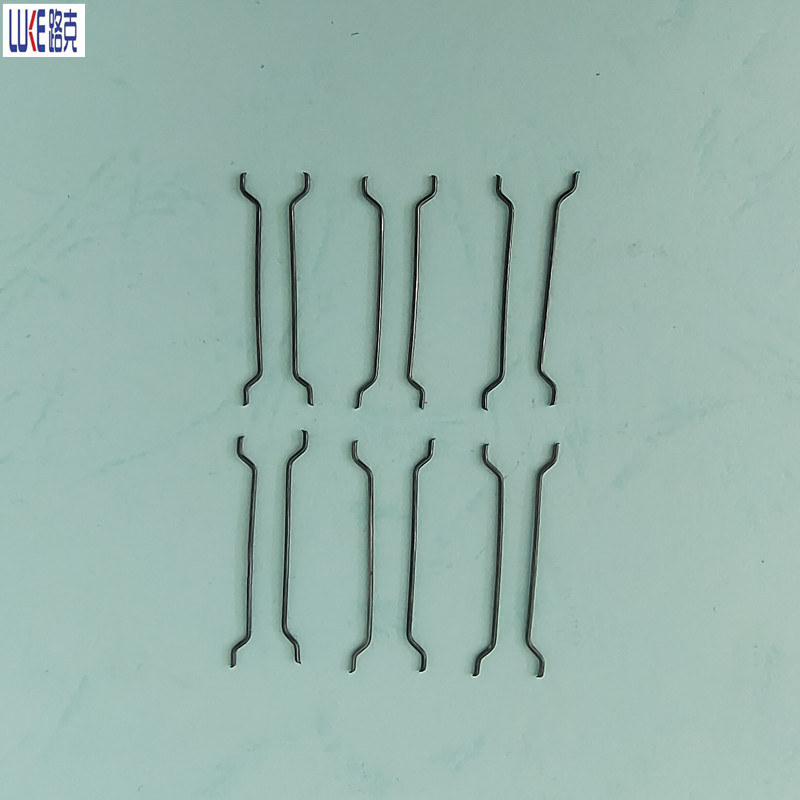

End hook steel fiber is a type of loose wire steel fiber, and this end hook design is generally considered to be the best anchoring form.Hooked end steel fibers are typically made from high-strength steel and have hooked ends to enhance their anchorage within the concrete matrix. When subjected to external deformation, it can slowly deform the hook end of the belt. When it is incorporated into concrete, the strength and hardness are higher, and it can withstand greater load and impact, and enhance the bearing capacity of concrete structure. It has the advantages of anti-cracking, anti-seepage, anti-settlement, etc., and it is more and more applied in engineering.

Key features and parameters of end hooked steel fibers:

Product Name | Steel Fiber Reinforcement | Place of origin | Shangdong,China |

Raw Material | High quality steel wire | Tensile strength(MPa) | ≥600 |

Shape | Hooked Steel Fiber | Equivalent diameter(mm) | 0.5-1.2 |

Length | 25~60mm | L/D ratio | 30-100 |

packaging | 20kg per bag | Application | Concrete Reinforced |

Benefits of Using Hooked Steel Fibers in Concrete:

◆Benefits of using hooked steel fibers in concrete:

◆Improve tensile strength: Steel fibers help to bridge cracks and distribute stress, increasing the tensile strength of concrete.

◆Enhanced toughness: The addition of steel fibers increases the energy absorption capacity of concrete, making it more resistant to impact and fatigue.

◆Crack control: The use of steel fibers reduces the width and spread of cracks and improves durability.

◆Reduce shrinkage cracks: Reinforced concrete steel fibers help alleviate plastic and dry shrinkage cracks.

◆Simplified construction: In some applications, steel fibers can partially or completely replace traditional rebar (steel bar or mesh), reducing labor and material costs.

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to fiber in a timely manner. Thank you for your love of our products.One-stop Service, Strict Quality Control!

About us:

Shandong Luke composite Co.,Ltd is a professional company on production and sales engineering anti-crack fiber. Concrete anti-crack fiber series such as polypropylene(PP) fiber、polypropylene(PP) mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber(end hook steel fiber,copper-coated steel fiber,corrugated steel fiber)、basalt fiber etc. Our polypropylene fibers have been exported to more than 30 nations and regions, such as Southeast Asia, Australia, North America, Europe, Middle East and Africa.The steel fiber price is good ,it is your best choice.

Professional equipment, high quality steel fibers, is your best choice, Welcome to request product prices!

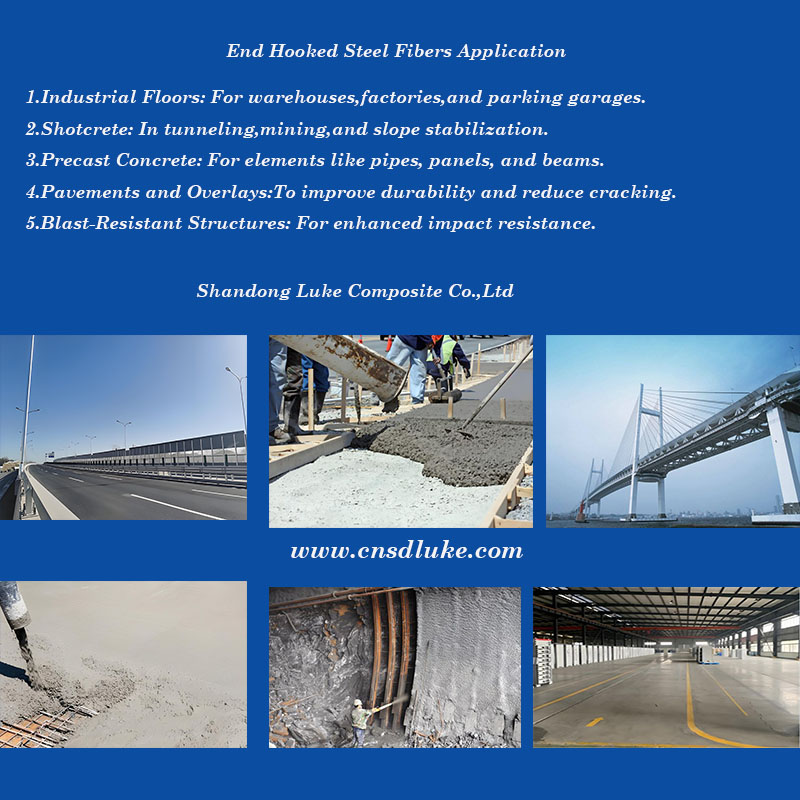

Application of steel fibers:

◆Industrial floors: Places that withstand heavy loads and wear.

◆Roads and Bridges: Improve crack resistance and durability.

◆Tunnels and mines: Enhanced impact and crack resistance.

◆Hydraulic engineering: Improve impermeability and durability.

◆Earthquake-resistant structure: improve the toughness and energy absorption capacity of the structure.

◆Special engineering: Enhanced knock and shock resistance.

◆Shotcrete and Sprayed Concrete:Enhances the toughness and durability of sprayed concrete used in tunneling, mining, and slope stabilization.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible